1.The Importance of Natural Gas Desulfurization

The acidic components such as H2S, CO2 and organic sulfur contained in natural gas will corrode metals in the presence of water; Sulfur containing components have the disadvantages of unpleasant odor, high toxicity, poisoning catalyst, etc. CO2 is a non-combustible gas, which not only affects the calorific value of natural gas, but also affects the efficiency of pipeline transportation. In particular, H2S is a gas with unpleasant rotten egg smell and great toxicity. If the content of H2S in the air reaches tens of mg/m3, it will cause tears and headaches. High concentration of hydrogen sulfide is life-threatening to people; H2S will severely corrode equipment and pipelines in the presence of water and at high temperatures (above 400 ℃); It also causes hydrogen embrittlement to some steels, and valve rod fracture and valve plate falling off in natural gas purification plants. Organic sulfur poisoning will cause nausea, vomiting and other symptoms, and may even cause heart failure, respiratory paralysis and death.

Therefore, natural gas desulfurization has the benefits of protecting the environment, protecting equipment, pipelines and instruments from corrosion and facilitating the use of downstream users.

At the same time, it can also turn harm for benefit and recycle resources. After the separation of hydrogen sulfide in natural gas, sulfur (bright yellow, purity up to 99.9) is made by Claus reaction. It can produce sulfur and sulfur-containing products, which are widely used in industry, agriculture and other fields.

The high-purity CO2 separated from natural gas with high content of CO2 can be used to make dry ice, and can also be used for re-injection formation on oil production to improve oil recovery.

2.Techniques for Desulphurization & Decarbonization of Natural Gas

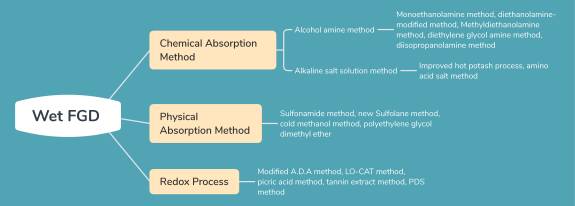

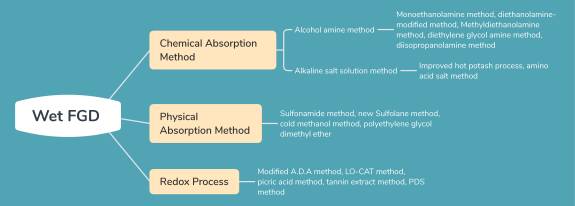

As for the removal of acid gas from natural gas, a number of techniques have been developed, which can be divided into wet and dry methods. Currently, dry desulfurization is rarely used in industry, and large-scale industrial units mainly adopt wet desulfurization. According to the absorption and regeneration methods of solution, wet desulfurization can be divided into chemical absorption, physical absorption and oxidation-reduction.