1.The Importance of Natural Gas Dehydration

lThe natural gas will be gradually cooled in the gas inlet and transportation pipeline, and the saturated steam in the natural gas will gradually precipitate to form water and condensate liquid. The liquid flows with natural gas and accumulates at the lower part of the pipeline, resulting in increased resistance. When the liquid accumulates to form slugs, its flow has great inertia, which will cause damage to the liquid catcher of the separator at the end of the pipeline.

lThe existence of liquid in the pipeline will reduce the transportation capacity of the pipeline.

lWater and other liquids in pipelines as well as hydrogen sulfide and carbon dioxide in natural gas form corrosive liquid, which causes corrosion in the pipeline, shortens the service life of the pipeline, and increases the frequency of pipeline bursts.

lWater is easy to form hydrate in the pipeline, which blocks the pipeline and affects normal production.

In order to protect the long-distance natural gas pipeline and improve the pipeline transportation efficiency, natural gas must be dehydrated before entering the gas pipeline.

2.Techniques & Features of Natural Gas Dehydration

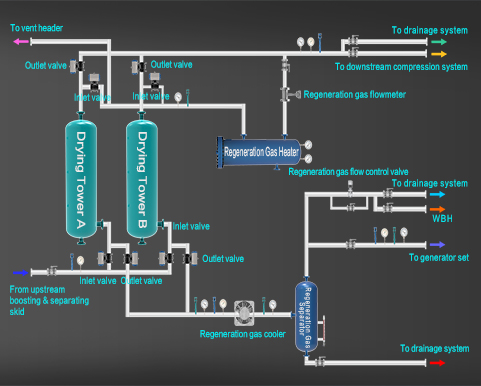

There are various techniques for natural gas dehydration. According to its principle, it can be divided into three categories: freezing and separation, solid adsorption drying and solvent absorption. Changqing Natural Gas Purification Plant adopts the triethylene glycol (TEG) dehydration process. The molecular formula of TEG is HO(CH2)2O·(CH2)2O·(CH2)2OH. TEG has the characteristics of strong water absorption and easy regeneration under high temperature, which can be used as a dehydrating agent to reduce the water content in natural gas. The dehydration process of TEG is a physical process, which uses the strong water absorption of TEG to absorb water in natural gas, and the TEG that absorbs water is called rich liquid; After the rich liquid enters the reboiler, the water is evaporated under normal pressure and high temperature. Coupled with dry gas stripping, a TEG lean liquid with a concentration of more than 99% can be obtained, which can be recycled. This process has the following characteristics:

l lSimple process flow, sophisticated technology, large dew point drop (30~60℃), excellent thermal stability, easy regeneration, less loss, low investment and operation costs, etc.

l lSetting the lean liquid cooling prior to the inlet of the circulating pump not only improves the operating conditions of the circulating pump, but also reduces the temperature of the product gas and reduces the impact on the pipeline transportation capacity of long-distance pipelines.

l lSet a filter on the rich liquid pipeline to remove the mechanical impurities and degradation products carried in the solution system, keep the solution clean, and facilitate the long-term operation of the unit.

lA medium pressure steam system specifically designed for TEG regeneration can be omitted.