1.Advantages of LNG

Since the volume of LNG is about 1/625 of the volume of gas before liquefaction, it is conducive to storage and transportation.

LNG can not only be used as a clean alternative fuel for gasoline and diesel, but also can be used to produce methanol, ammonia and other chemical products. In addition, LNG has been widely used in gas peak regulation and emergency gas sources, improving the stability of gas supply for urban residents and industrial users. The evaporation phase change during LNG regasification (about 510 kJ/kg at -161.5°C) can also be used in cryogenics, refrigeration and other industries.

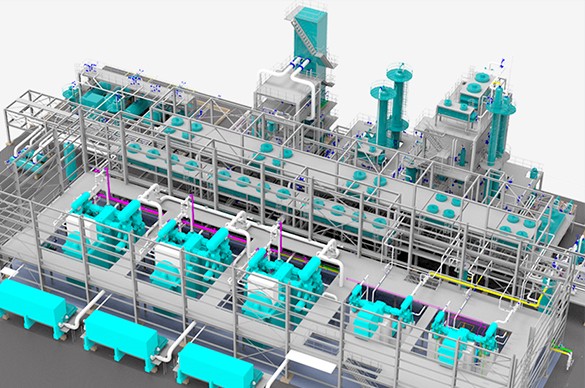

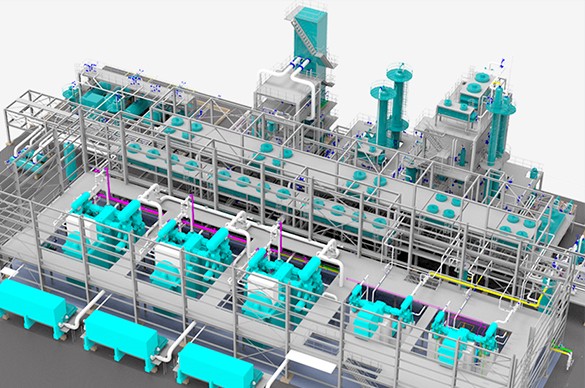

2.LNG Production Process

LNG production generally includes natural gas pretreatment, liquefaction and storage, of which the liquefaction system is the core. Generally, the natural gas is pretreated to remove the components unfavorable to the liquefaction process, and then enters the high-efficiency low-temperature heat exchanger in the liquefaction part to continuously cool down and separate out the heavy hydrocarbons. Finally, the temperature is reduced to -162 ℃ (or slightly higher temperature) under normal pressure (or slightly higher pressure), so as to obtain LNG products, which can be stored, shipped and used under normal pressure (or slightly higher pressure).

3.Feed Gas Pretreatment

The feed gas of LNG plant comes from conventional natural gas, such as gas reservoir gas, condensate gas and associated gas in oil and gas fields, as well as unconventional natural gas, such as coalbed methane, which generally contain H2S, CO2, organic sulfur, heavy hydrocarbons, water vapor, mercury and other impurities to varying degrees. Thus, it is necessary to carry out pretreatment before liquefaction.

Feed gas pretreatment process includes:

1. Desulfurization and decarbonization

2. Dehydration

3. Heavy hydrocarbon removal

4. Mercury removal

5. Denitrification and deoxidation

4.Natural Gas Liquefied Process

After pretreatment, the feed gas enters the heat exchanger of the liquefaction system to keep cooling until liquefaction. Therefore, the core of natural gas liquefaction process is the refrigeration system.

Generally, the liquefaction process of natural gas can be divided into:

Throttling refrigeration cycle

Expander refrigeration cycle

Cascade refrigeration cycle

Hybrid refrigerant refrigeration cycle

Hybrid refrigerant refrigeration cycle with precooling.

Currently, the last three liquefaction processes are mainly used in base-load LNG plants in the world.

5.LNG Storage & Transportation

LNG shall be stored in storage tanks. In LNG terminals, there are also a certain number of tanks of different sizes. Because natural gas is flammable and explosive, and the storage temperature of LNG is quite low, its storage capacity and facilities are required to be safe, reliable and efficient.

There are two main ways for the LNG transportation. Generally, LNG tankers are used on land and LNG ships are used at sea. In recent years, due to the technological development, there are also ways to transport LNG by trains and large containers.