Natural gas will carry a large amount of gas or solid impurities when it is extracted from the formation. If it is not treated, it will cause great damage to the gas transmission pipeline and downstream equipment. Therefore, the filter separator must be used to remove the liquid and solid impurities in the water bearing natural gas before gathering and transferring.

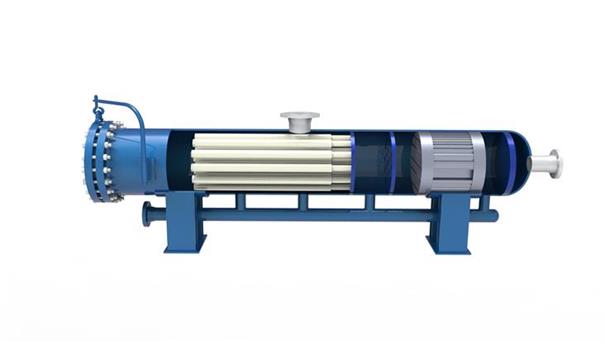

The filter separator is mainly composed of cylindrical glass fiber filtering element and stainless steel wire demisting net. The filter separator can be horizontal or vertical. The most common type is horizontal. If there is a large amount of water in the incoming gas, the structure of the filter separator is designed to have a "sleeve" at the bottom of the separator, which is connected with two similar pipes parallel to each other. The retention time required for precipitation separation of hydrocarbon (oil) - water is 3-5 minutes. The size of each part of the filter separator depends on the calculation and design of the manufacturer or engineering company.

Filter separator is widely used in gas pipeline and gas treatment plant (such as deacidification unit). After passing through the filter, the separator will capture the liquid from the absorber and condensed hydrocarbon. In gas treatment, there are sufficient entrance separators and filter separators to prevent foam formation due to chemical contamination. If the absorber is located downstream of the amine unit, glycol unit or compressor, a filter separator is required.

Our company has unique technology in the design and manufacture of filter separator. Our engineering and technical team can face any challenge and provide the most reasonable solution according to the specific needs of customers. Contact us for more information.