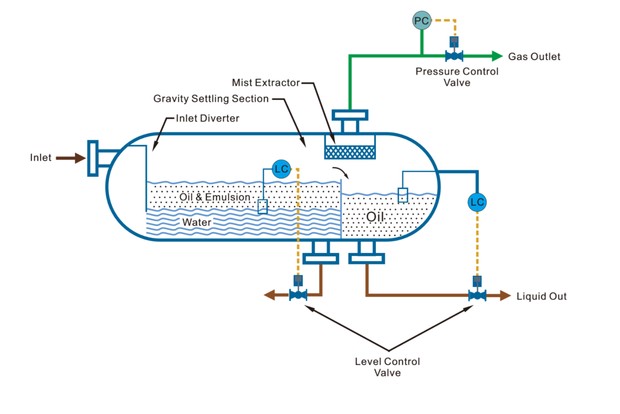

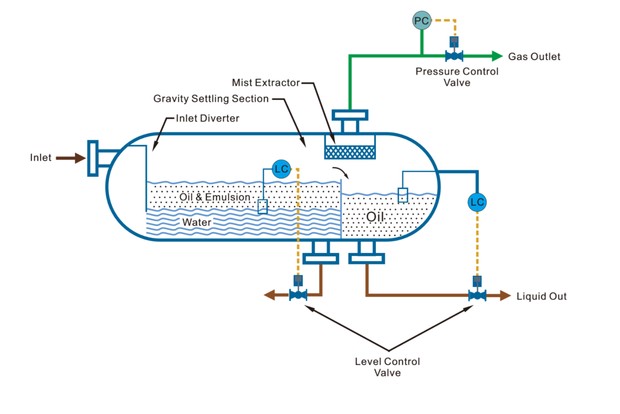

It is mainly used for the three-phase separation of oil/gas/water in the production of oil or gas wells. It is not only necessary to separate liquid and gas, but also to separate oil and water in liquid. Oil, gas and water flow through different pipelines to the next link. Three phase separator is more widely used than gas-liquid two-phase separator and oil-water two-phase separator. Correspondingly, there are more complicated internals.

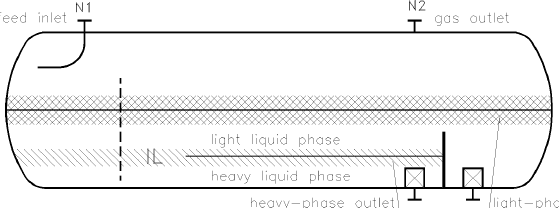

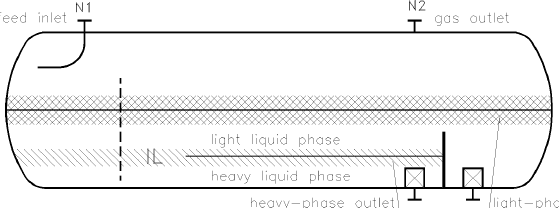

The basic difference between the three-phase separator and the two-phase separator is that the three-phase separator must be equipped with weir plate. The weir plate is an isolation plate with a certain height, which is installed at the end of the separator. In the process of oil-water separation, the oil-water mixture moves from the inlet to the end of the separator, and the oil floats gradually due to the low density, while the water gradually decreases. However, when the weir plate height is appropriate, only oil can flow over the weir plate and leave the separator from the oil outlet pipeline. Water is stopped in front of the weir plate and flows out from the water outlet of the lower part of the container in front of the weir plate.

Product category:

1. Ordinary three-phase (oil-gas-water) separator

Purpose: crude separation of oil, gas and water in low dispersion condition

2. Three phase separator with wire mesh mist eliminator

Purpose: crude separation of oil, gas and water in low dispersion condition

3. Oil-water separator with corrugated plate / orifice plate corrugated packing

Purpose: fine separation without considering dispersion degree

Horizontal Separator / Vertical Separator

The assembly form of the three-phase/two-phase separator is mainly divided into two types: vertical and horizontal.

The horizontal separator is of horizontal structure, in other words, its container shell axis is parallel to the ground. It is usually used for the treatment of fluid with large liquid/gas ratio or liquid/liquid separation. Compared with the vertical separator, the horizontal flow cross-sectional area of liquid flow is larger, and the vertical section of gravity separation of liquid with different densities is shorter.

The horizontal separator is not affected by the wind in the application process due to its large ground contact area. It has the advantages of stable structure and convenient operation.

Horizontal separator can be used for test separator, production separator, two-phase separator (liquid-liquid / oil-water separator), three-phase separator (oil-gas-water separator) and special application separator.

Vertical separator is arranged in a vertical configuration, that is, the shell axis is perpendicular to the ground. In contrast to the horizontal separator, the cross-sectional area of gas horizontal flow is larger, and the vertical area of liquid gravity separation is larger. Because of its small ground contact surface, it is not wind-resistant and has poor stability. Therefore, the site wind environment should be considered. The advantage is space-saving.

The vertical separator can be used for test separator, production separator, two-phase separator (liquid-liquid / oil-water separator), three-phase separator (oil-gas-water separator) and special application separator.

At present, horizontal separator is commonly used in China.

- Can deal with the crude separation of a large amount of liquid and gas;

- High separation speed and precision;

- Advanced control system, high degree of automation, easy to operate;

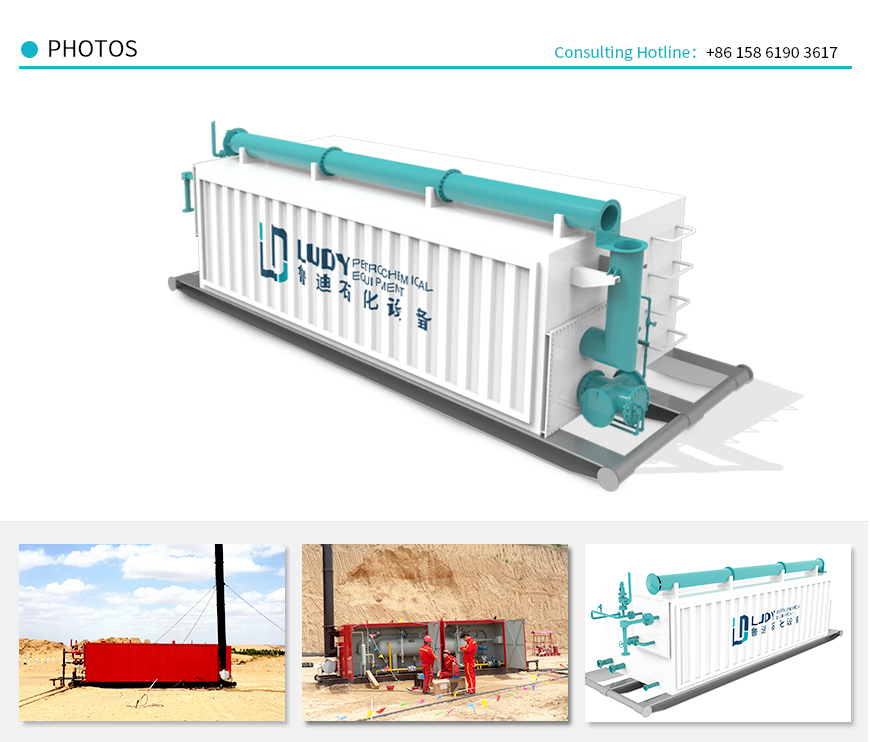

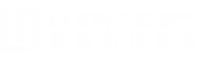

- Skid-mounted design, convenient for hoisting and transportation, saving transportation cost;

- High security with its less occupied area;

- Compact and reasonable structure design, integration of a variety of measuring instruments and control equipment;

- Compatible with multiple control modes (direct + PLC + computer + DCS);

- Reliable quality, can match parts according to the brand specified by customers, such as instruments and valves.

Mainly used in oil, natural gas and petrochemical industries to separate the oil when there is water in the oil and the oil in the water.

Max. design pressure: 9.8MPa (1400psi)

Max. normal working pressure: <9.0MPa (?psi)

Max. design temp.: 80℃

Liquid handling capacity: ≤300m³/ d

Inlet pressure: 32.0MPa (4640psi)

Inlet air temp.: ≥10℃ (50°F)

Processing medium: crude oil, water, associated gas

Set pressure of safety valve: 7.5MPa (HP) (1088psi), 1.3MPa (LP) (200psi)

Set pressure of rupture disk: 9.4MPa (1363psi)

Gas flow measurement accuracy: ±1%

Liquid content in gas: ≤13mg/Nm³

Oil content in water: ≤180mg/ L

Moisture in oil: ≤0.5%

Power supply: 220VAC, 100W

Physical properties of crude oil: viscosity (50℃); 5.56Mpa·S; crude oil density (20℃):0.86

Gas-oil ratio: > 150

We can also customize according to specific needs, please feel free to contact us.

.png)

Note: the data in this table are common equipment parameters for reference only. We can also provide customized equipment according to specific requirements.

.png)