Compressed Natural Gas (CNG for short), is a gaseous natural gas compressed to a pressure greater than or equal to 10MPa and not greater than 25MPa. At temperatures higher than -82.5°C, no matter how much pressure is added, methane will not liquefy. In order to store more gas or reduce the size of gas storage vessel at atmospheric temperature, only compression can be performed. CNG is natural gas that is pressurized and stored in vessel in a gaseous state.

In addition to natural gas production from oil fields and natural gas fields, compressed natural gas can also be produced using artificial biogas, which is mostly methane. CNG can be used as vehicle fuel. A CNG-fueled vehicle is called NGV (Natural Gas Vehicle).

CNG can also be used to make LNG (namely liquefied natural gas).

Natural gas processing

.jpg)

Compressed natural gas processing technology

I. Natural gas desulfurization

Sulfide in natural gas: hydrogen sulfide, mercaptan, carbon disulfide, etc.

Main methods of natural gas desulfurization:

1. Chemical solvent method: alcohol amine method, organic hot potash method.

2. Chemical-physical solvent method: sulfone amine method

3. Physical solvent method - cold methanol method: desulfurization by using the difference in solubility of hydrogen sulfide, carbon dioxide, methane, etc. in the solvent.

4. Direct regeneration method: the alkaline solution containing oxidant is used to remove hydrogen sulfide and oxidized to elemental substance, and the oxidant is regenerated with air, such as anthraquinone method.

5. Adsorption method: molecular sieve, membrane separation, etc.

Ⅱ. Natural gas dehydration

1. Purpose of dehydration:

It refers to the process of removing water vapor from natural gas by absorption to make its dew point meet certain requirements. The extracted natural gas contains saturated water vapor. Water is a harmful and unhelpful component of natural gas because:

1) It reduces the calorific value of natural gas and the transmission capacity of gas transmission pipeline.

2) When the temperature decreases, the water will accumulate as liquid phase and corrode the equipment.

3) When water is at freezing point, it will freeze and block pipes, valves and equipment. Therefore, the water vapor shall be removed to the dew point or the water content shall meet the pipeline transportation requirements before exporting. In addition, in order to prevent the natural gas from forming hydrate or ice blockage in the low-temperature system of light hydrocarbon recovery unit, it shall also be deeply dehydrated. Dew point drop is usually used to indicate the dehydration depth or effect of natural gas.

4) Dew point drop: the difference between the dew point of feed gas before dehydration and that of dry gas after dehydration.

5) In light hydrocarbon recovery, the water content of gas is required to be less than 1PPM.

2. Dehydration method:

Solvent absorption method, solid adsorption method, low temperature separation method and membrane separation technology.

Ⅲ.Light hydrocarbon recovery

1. Light hydrocarbon recovery - natural gas liquids recovery: The process of recovering hydrocarbon mixtures such as ethane, propane, butane and pentane from natural gas is called natural gas liquids (NGL) recovery, which is traditionally called light hydrocarbon recovery.

2. The recovered NGL is divided into several products: ethane, propane and butane (liquefied petroleum gas), C5+ (natural gasoline, light oil).

3. Currently, oil absorption method, adsorption method and condensation method (low temperature separation method) are mainly used.

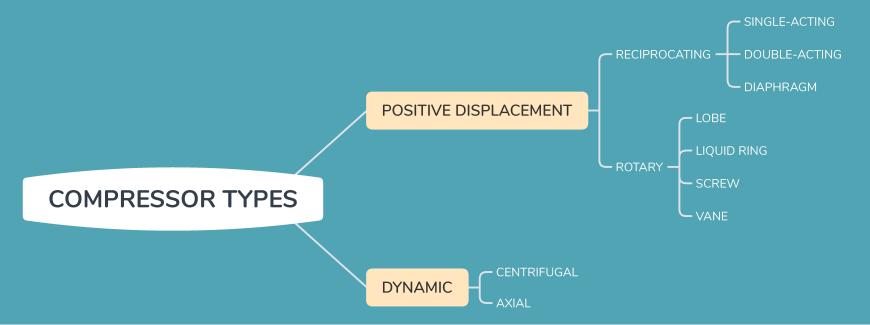

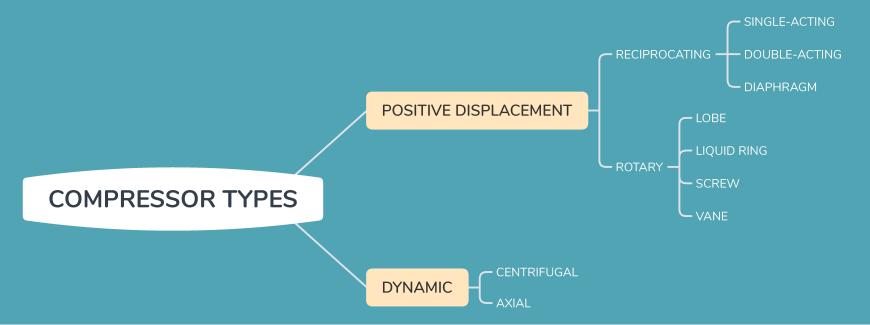

Ⅳ. Natural gas compression

1. Centrifugal compressor

Structure of centrifugal compressor:

- Horizontal split centrifugal compressor

- Vertical split centrifugal compressor

- Isothermal compression centrifugal compressor

2. Reciprocating compressor

According to the shaft power and exhaust volume, it can be divided into micro, small, medium and large.

The types of compressors without liquid lubrication are:

- Non-lubricated compressor

- Non-contact type (labyrinth seals) compressor

- Diaphragm compressor

Application of CNG

CNG is the most ideal alternative energy for vehicles. It has the characteristics of low cost, high efficiency, no pollution, safe and convenient use, and is increasingly showing promising development potential. Natural gas filling stations are generally divided into three basic types, namely fast filling type, ordinary (slow) filling type and mixed type of the two. CNG is also used in city gas industry, especially residential fuel. With the improvement of people's living standards and the enhancement of environmental protection awareness, the demand for natural gas in most cities has increased significantly. The economic benefit of natural gas (pipeline natural gas) as civil fuel is also greater than that of industrial fuel.

主图.jpg)

.jpg)