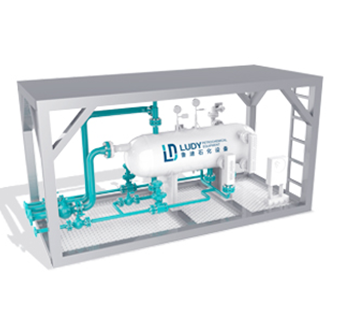

Used for gas-liquid separation. For the oil-gas mixture extracted from crude oil or natural gas well, when only gas and liquid are required to be separated, a gas-liquid two-phase separator is needed. The separator can be horizontal or vertical, the former is more conducive to the treatment of a large amount of liquid, and the latter is more conducive to the treatment of a large amount of gas. At the same time, the horizontal type is preferred when the height of installation space is limited, and the vertical type is preferred when horizontal dimensions are limited.

Product classification:

1.1 Ordinary gas-liquid separator

Purpose: gas-liquid crude separation

1.2 Gas-liquid separator with wire mesh mist eliminator

Purpose: gas-liquid separation, and to avoid separated gas with droplets

1.3 Gas-liquid separator with corrugated plate/orifice corrugated packing

Purpose: gas-liquid separation, and to avoid separated gas with droplets

1.4 Gas-liquid separator with cyclone

Purpose: gas-liquid separation and mist removal under high fouling condition

Horizontal/Vertical Separator

The assembly forms of three-phase/two-phase separator is mainly divided into two types: horizontal and vertical.

Horizontal separator is of horizontal structure, in other words, its shell axis is parallel to the ground. It is usually used for the treatment of fluid with large liquid/gas ratio or liquid/liquid separation. Compared with the vertical separator, the horizontal flow cross-sectional area of liquid flow is larger, and the vertical section of gravity separation of liquid with different densities is shorter.

Horizontal separator is not affected by the wind in the application process due to its large ground contact area. It has the advantages of stable structure and convenient operation.

Horizontal separator can be used for test separator, production separator, two-phase separator (liquid-liquid / oil-water separator), three-phase separator (oil-gas-water separator) and special application separator.

Vertical separator is set in vertical form, that is, the shell axis is perpendicular to the ground. Contrary to the horizontal separator, the cross-sectional area of the horizontal flow of gas is larger, and the vertical area of the liquid gravity separation is larger. Due to its small ground contact surface, it is not wind-resistant and has poor stability. Therefore, It needs to be used in consideration of the on-site wind environment. It has the advantages of less occupied area.

Vertical separator can be used for test separator, production separator, two-phase separator (liquid-liquid / oil-water separator), three-phase separator (oil-gas-water separator) and special application separator.

- Not limited to production decline

- High congestion flow processing capacity

- Liquid removal efficiency > 98%

- Internal parts are not easily to be damaged

- Sensitive to liquid slug flow

Mainly used in petroleum, natural gas and petrochemical industries. For oil and gas mixtures extracted from crude oil or natural gas wells, only the separation of gas and liquid is required.

.png)

.png)

.png)

.png)