In the production process of oil and gas wells, oil and water will be mixed together by external force, in order to be extracted with the state of water-in-oil and oil-in-water. This requires the use of a separator to separate it, oil as an output to the next stage of production, water to be discarded or refilled, or treated as domestic water for oilfield construction sites, etc.

Product classification:

1.1 Ordinary oil-water separator

Purpose: coarse separation of the medium with good separation characteristics (i.e. relatively low liquid viscosity, not high oil-water dispersion degree, relatively large dispersed droplets, clear interface between oil-water droplets and the surrounding water and oil)

1.2 Oil-water separator with inclined plate

Purpose: fine separation under the condition of low dispersion

1.3 Oil-water separator with corrugated plate / orifice plate corrugated packing

Purpose: fine separation without considering dispersion degree

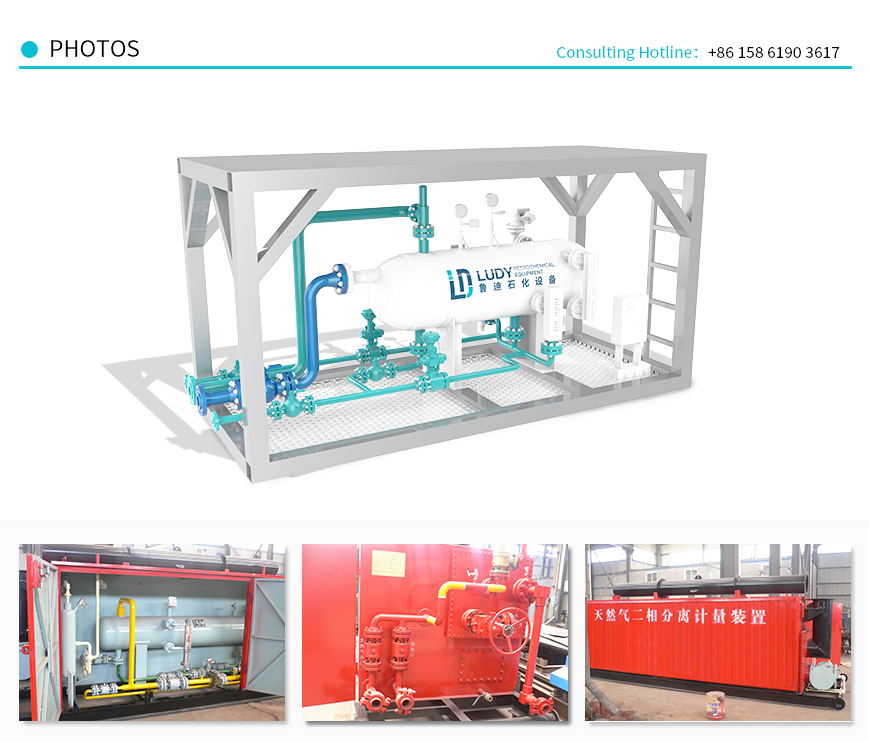

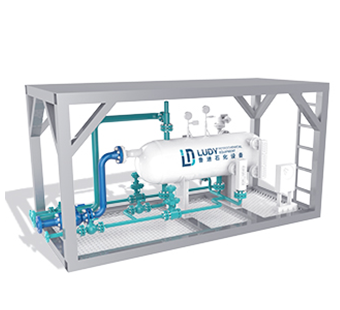

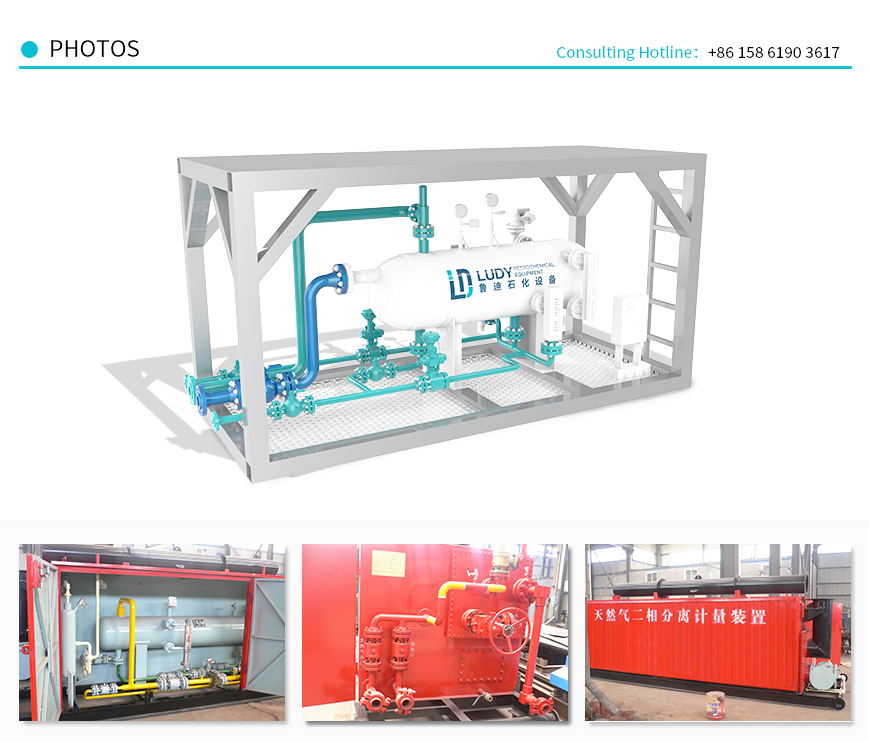

Horizontal/Vertical Separator

The assembly forms of three-phase/two-phase separator is mainly divided into two types: horizontal and vertical.

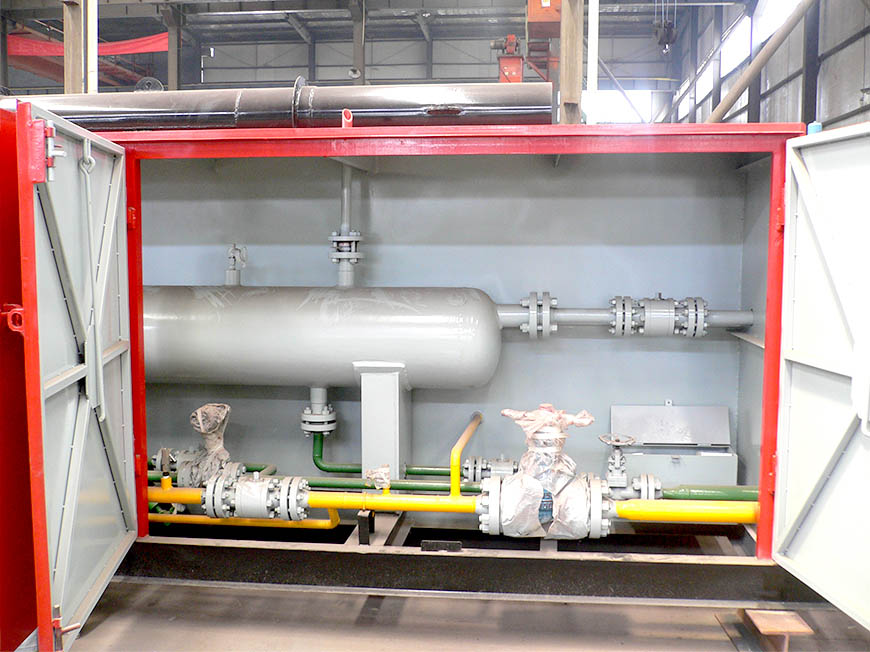

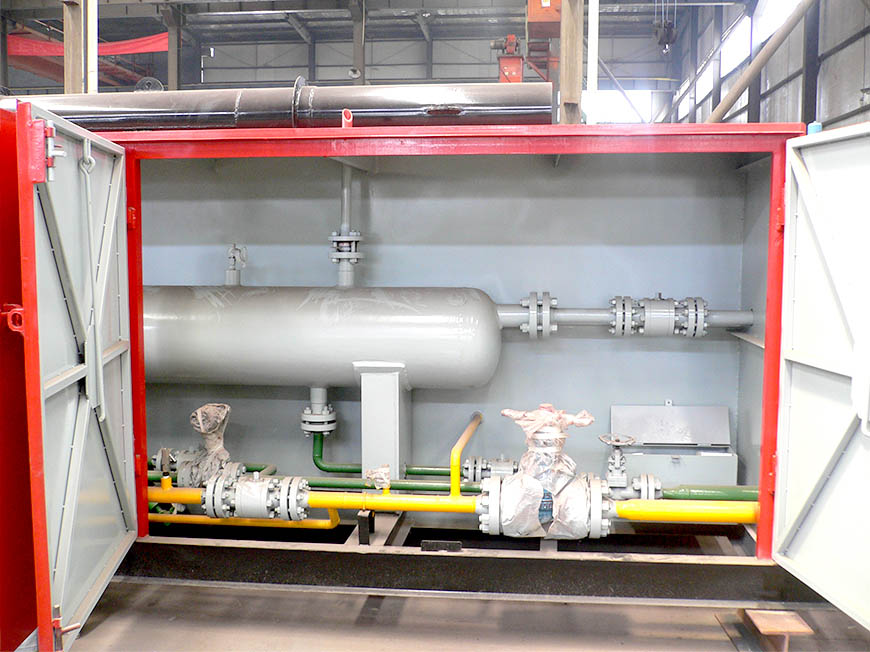

Horizontal separator is of horizontal structure, in other words, its shell axis is parallel to the ground. It is usually used for the treatment of fluid with large liquid/gas ratio or liquid/liquid separation. Compared with the vertical separator, the horizontal flow cross-sectional area of liquid flow is larger, and the vertical section of gravity separation of liquid with different densities is shorter.

Horizontal separator is not affected by the wind in the application process due to its large ground contact area. It has the advantages of stable structure and convenient operation.

Horizontal separator can be used for test separator, production separator, two-phase separator (liquid-liquid / oil-water separator), three-phase separator (oil-gas-water separator) and special application separator.

Vertical separator is set in vertical form, that is, the shell axis is perpendicular to the ground. Contrary to the horizontal separator, the cross-sectional area of the horizontal flow of gas is larger, and the vertical area of the liquid gravity separation is larger. Due to its small ground contact surface, it is not wind-resistant and has poor stability. Therefore, It needs to be used in consideration of the on-site wind environment. It has the advantages of less occupied area.

Vertical separator can be used for test separator, production separator, two-phase separator (liquid-liquid / oil-water separator), three-phase separator (oil-gas-water separator) and special application separator.

- Sensitive to scaling

- Fast separation speed

- Advanced control system, high degree of automation and easy operation

- Skid-mounted design, convenient for hoisting and transportation, saving transportation cost

- High safety

- Compact and reasonable structure design, integration of a variety of measuring instruments and control equipment

- Compatible with multiple control modes (direct + PLC + computer + DCS)

- Reliable quality, such as instruments and valves, which can be matched with the brand specified by customers

Mainly used in petroleum, natural gas and petrochemical industries to separate oil or water in the state of water-in-oil and oil-in-water.

.png)

.jpg)

.png)

.jpg)