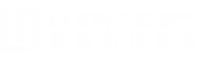

Multi-cyclone separator is an important device that removes solid particles and liquid droplets from the feed gas to protect subsequent equipment or extend the service life of filter elements in subsequent vessels or meet certain process requirements.

The multi-cyclone separator produced by Jiangsu Ludy Petrochemical Equipment is designed to remove 100% of all liquid particles of 8.0μm and above, as well as 100% of all solid particles and 99% of 5-8μm and liquid particles when operating under design conditions. No more than one tenth of a gallon of entrapment liquid per MMscf gas is allowed to pass through the outlet when operating under the pressure and flow parameters specified by the plant.

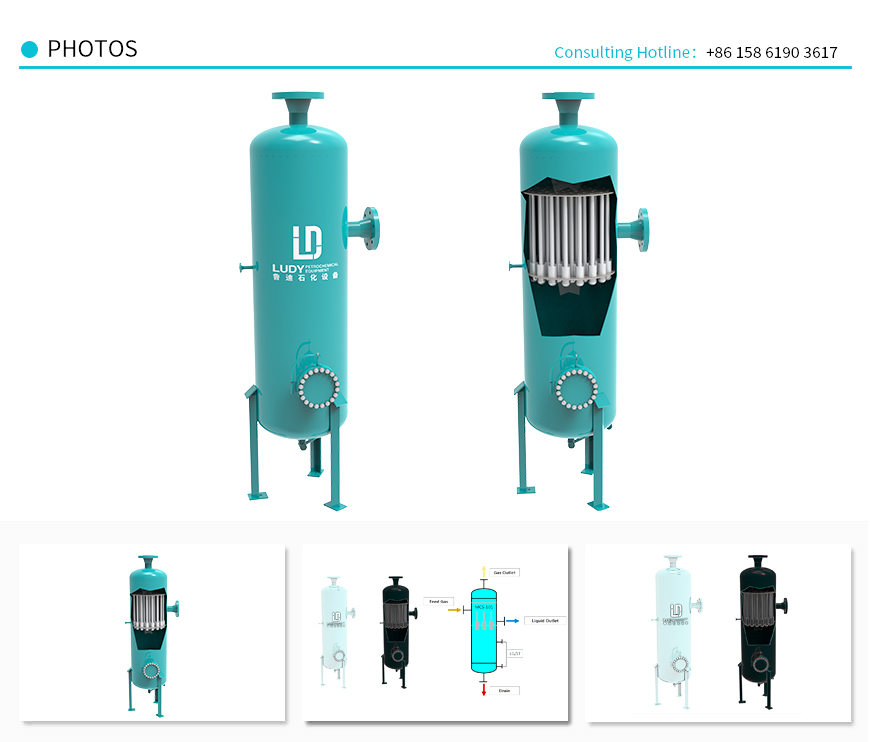

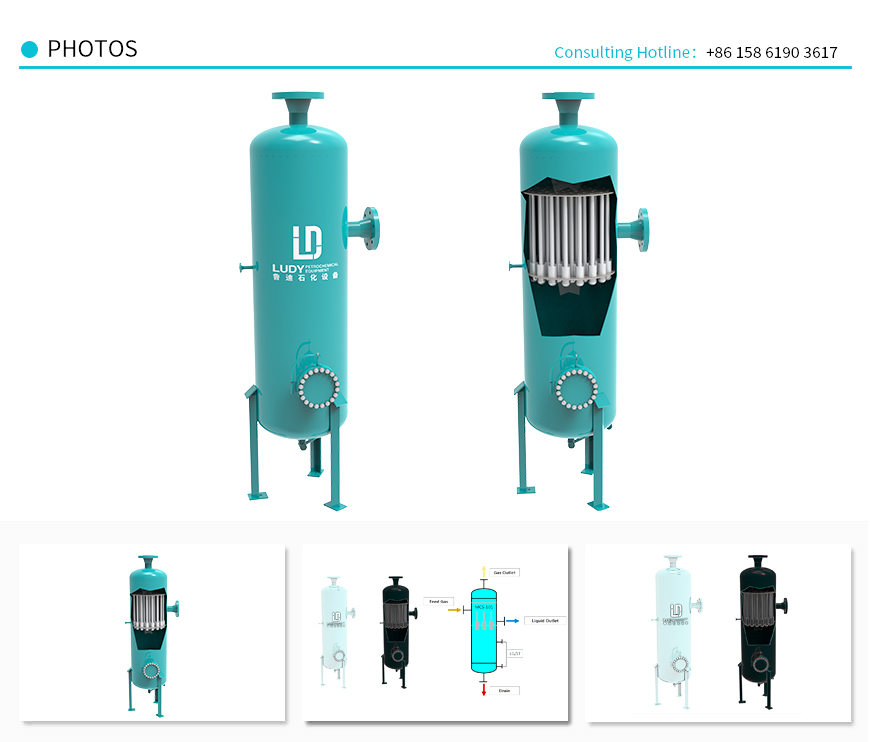

The multi-cyclone separator is manufactured with well-designed separation segments and the physical principles of centrifugal force, impact force and gravity.

The saturated gas enters the first stage intake chamber of the separator, which contains a cyclone separator riser arranged in a parallel structure. In this chamber, the velocity of air flow is significantly reduced, and a large amount of liquid and solid rapidly fall into the bottom of tube plate with cyclone separator. The riser support tube will be further separated. As the liquid passes through the labyrinth tube, it impinges on the riser, with 5-10μm of particles coalescing on the riser and flowing down to the cyclone plate.

The gas then enters a number of cyclone tubes arranged on the bottom tube plate. Each cyclone separator has two tangential entry points, forcing the gas to flow counterclockwise downward, increasing its velocity, and exerting a small radius of centrifugal force on the solid and liquid particles. The particles are then thrown down through the vortex of the cyclone tube into the sump, where the washed gas rises to the outlet of the vessel through a well-designed riser.

- Wear-resistant material: made of alloy steel of cyclone separator and 316 stainless steel can also be provided;

- Low maintenance cyclone elements with self-cleaning; only regular drainage is required to remove the collected materials;

- No washing oil or liquid is used;

- Larger flow range compared with the centrifugal separator;

- Large capacity with each design scheme; options are single layer, double layer, vertical and horizontal. Cyclone separator elements are available in two sizes;

- To determine the size according to the application to achieve the optimal flow rate of each cyclone tube;

- Optional cyclone speed reducer to keep the internal speed at the specified level, so as to achieve the highest efficiency in the production range of various processes;

- Cost-effective, efficient solid-liquid removal, guaranteed performance and maintenance free.

Multi-Cyclone Scrubber Centrifugal Separator can be used in applications requiring high efficiency dust removal and liquid removal:

- Chemical fertilizer production

- Natural gas compression

- Oil refineries

- Power plant

- Industrial steam

- Industrial gas compression

- Air separation

- Petrochemical industry

- Chemical production (e.g., methanol)

- LNG production

- Plastic production

Jiangsu Ludy is an experienced professional manufacturer of multi-cyclone separator. We provide a variety of separators and skid-mounted separators for oil and gas facilities. Our natural gas separator is widely used in domestic and international markets. Please feel free to contact us for technical support and favorable quotation of multi-cyclone gas-liquid separator.