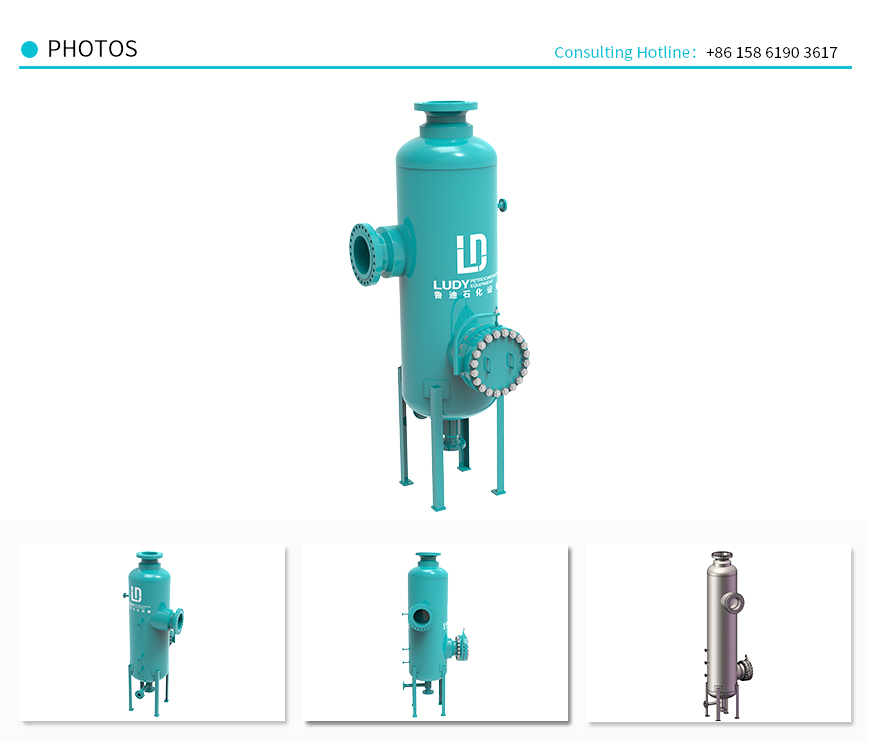

Jiangsu Ludy is a professional manufacturer of cyclone separator for natural gas pipeline and natural gas processing equipment.

Jiangsu Ludy is able to design and manufacture high-quality gas cyclone separators, which can meet customer expectations in terms of quality and process performance. We also offer gas cyclones that are integrated into the whole system and can be equipped with automatic control systems.

Meanwhile, Jiangsu Ludy can design and supply various products for the oil and gas industry. If you need complex technical solutions of three-phase separator, two-phase separator, test separator, production separator, water bath heater, crude oil heater, natural gas heater, filter separator, dry gas filter and natural gas H2S-removal device, please feel free to contact us.

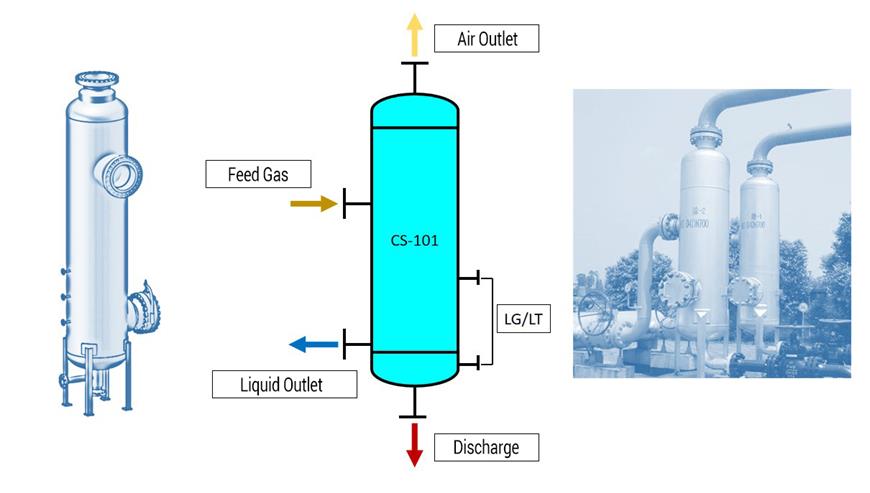

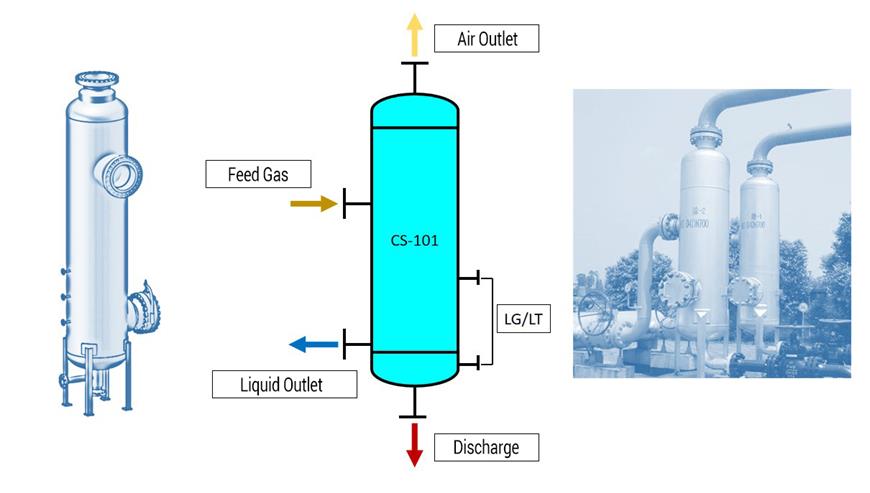

Natural gas circulation separator is one of the forms of cyclone separator. As we all know, cyclone separator is a kind of equipment which uses centrifugal force to remove particles from gas. The gas entering from the inlet rotates and descends along the cylinder wall and flows towards the apex of the cone. Then it reverses the axial flow direction from the apex of the cone to rise with a gradually expanding spiral line, and finally it is discharged by the exhaust pipe. Since the air flow drops and then rises, this kind of cyclone separator is also known as reflux type. In the process of rotating downward and upward airflow, particles entrained in the air flow are thrown onto the wall along the outer spiral to the inner spiral of the separator. The centrifugal force on particles is greater than that of gravity. For example, the centrifugal force of the cyclone separator with small diameter and high resistance is 2500 times larger than that of gravity. Large diameter and low resistance should be at least 5 times larger. Its inlet velocity is 10~30m/s, and the pressure drop is generally in the range of 10~200mm water column. Under normal conditions, it can capture particles larger than 20μm.

The commonly used cyclone separator is developed into a circulation separator after improvement. It is divided into two effective separation sections: in the first stage, all free droplets and most of the liquid in the gas are thrown out by centrifugal force; in the second stage, a small amount of liquid sandwiched in the gas is thrown out by increasing the centrifugal force. This kind of separator is also called internal circulation separator, where the internal flow is centripetal flow, which means that all the airflow flows to the center, as in the vortex center. The fluid enters the separator through the tangential nozzle, and the air flow rotates along the inlet chamber, and then it moves down between the smooth sleeve and the shell into the cyclone chamber. The liquid is thrown to the wall of swirl chamber by centrifugal action. The gas still rotating converges to the center of the pipe through the baffle, and its velocity increases and enters the exhaust pipe. At this time, the liquid remaining in the fast flow is thrown to the inner wall of the exhaust pipe and swept along the wall to the gas outlet. Then the liquid, together with the gas branch of about 10% of the total gas volume, is sucked out through the gap on the pipe wall, enters the circulation pipeline and returns to the swirl chamber through the central hole of the baffle plate. The suction comes from the low pressure area in the center of the vortex. After entering the vortex chamber, the liquid and side flow gas from the circulation pipeline are immediately mixed with the rapidly rotating gas, and the liquid is thrown to the pipe wall again. At this time, the main gas flow which has been deliquified continues to go up and discharge from the exhaust pipe through the seam.

According to the relevant data, the static pressure value of the inner wall of the separator is positive, while that of the axial part is negative, because when the separator is connected by pipelines, a circulating flow from high pressure to low pressure will appear.

The practice shows that the natural gas circulation separator has the following advantages:

1. It is suitable for gas-liquid two-phase separation, such as gas-liquid separation for oil-gas fields in Sichuan Province;

2. The separation efficiency is over 99%;

3. The maximum pressure drop is less than 0.01MPa;

4. It has strong adaptability and can operate effectively at the inlet speed of 1.58~19.43m/s;

5. Reliable operation, convenient maintenance and repair, and easy manufacturing;

6. Small size, light weight, convenient transportation and simple installation;

7. High cost-performance.

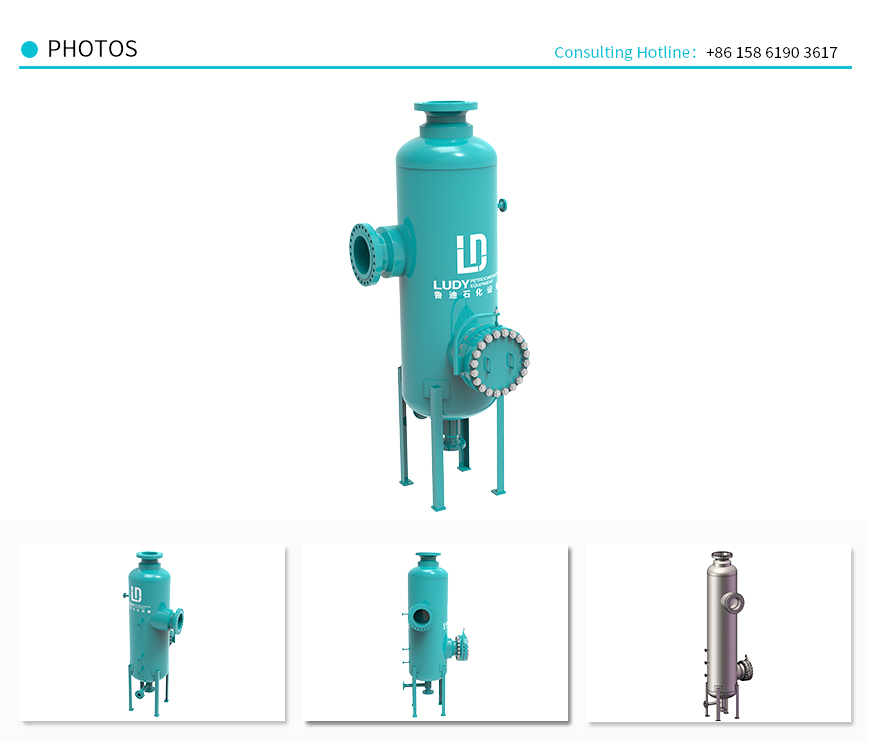

Cyclone Separator

Cyclone separator, also known as centrifugal separator, is composed of cylinder, conical tube, threaded blade, central tube and liquid collecting bag. The main feature of cyclone separator is that the gas and separated liquid enter the separator at a certain speed along the tangential direction of the cylinder wall, and rotate along the inner wall of the separator. Because the density of the separated droplets is much higher than that of the gas, the droplets are thrown to the cylinder wall and attached to the cylinder wall in this rotary motion. The droplets gather together and flow downward along the cylinder wall, and finally flow into the collector section of the separator and are discharged.

The cyclone separator has small volume and high efficiency, but its separation effect is very sensitive to the convection velocity. Therefore, the processing load of the cyclone separator is generally required to be relatively stable, which limits the application scope of the cyclone separator.