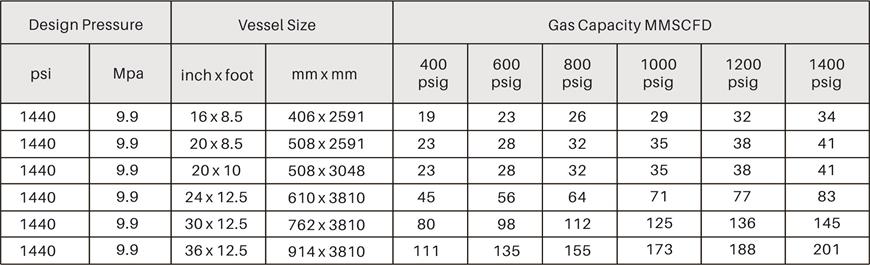

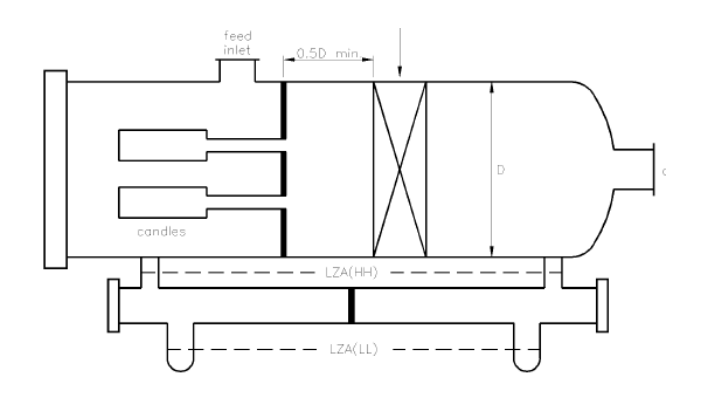

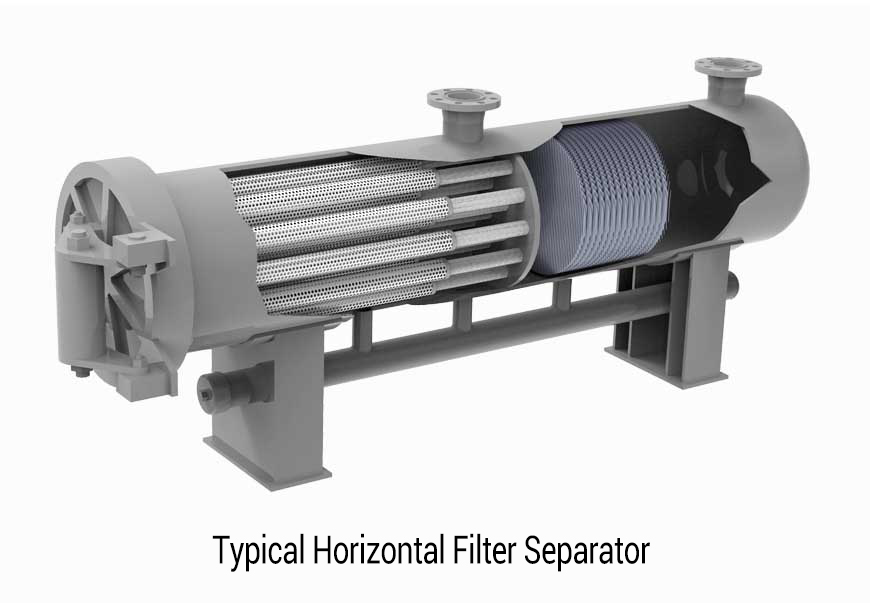

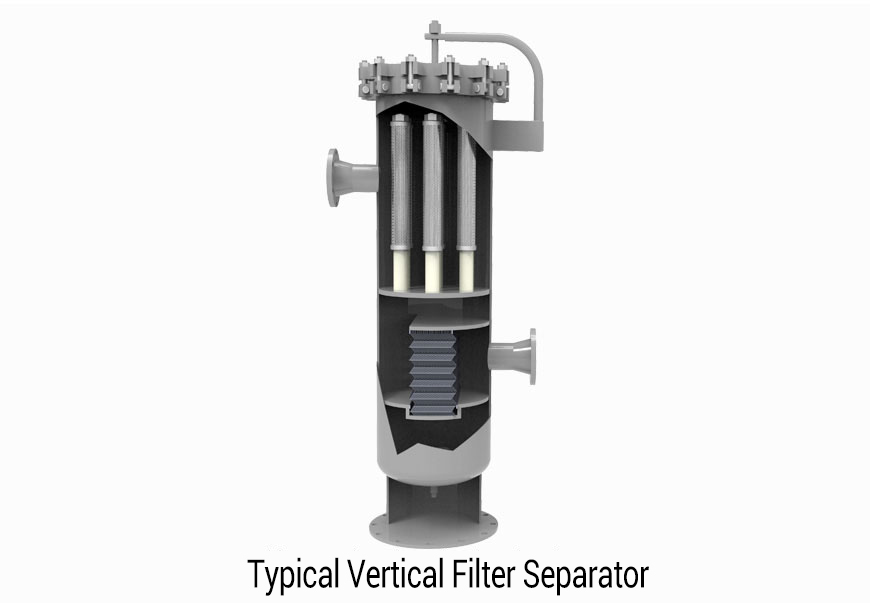

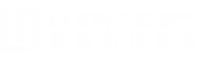

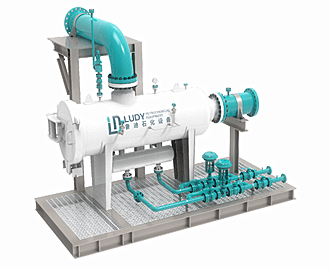

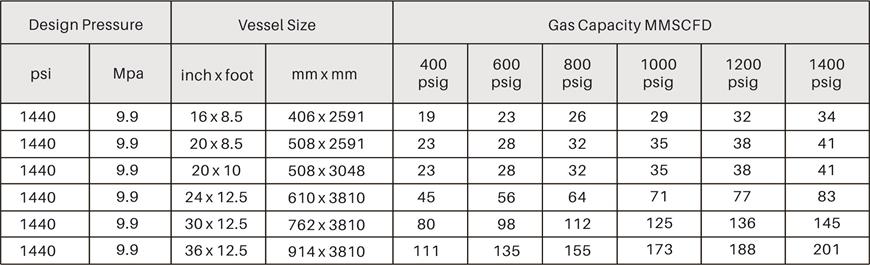

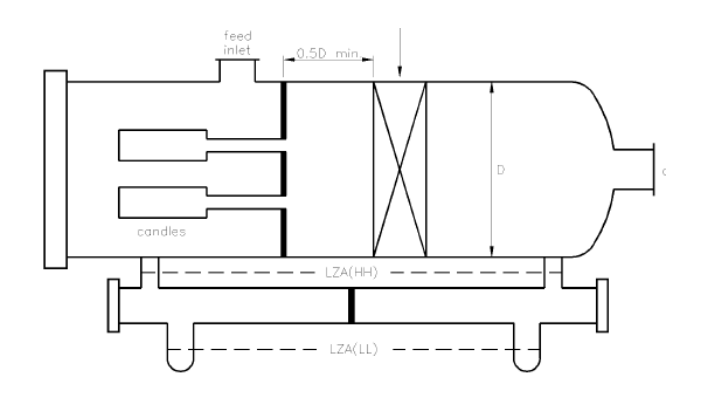

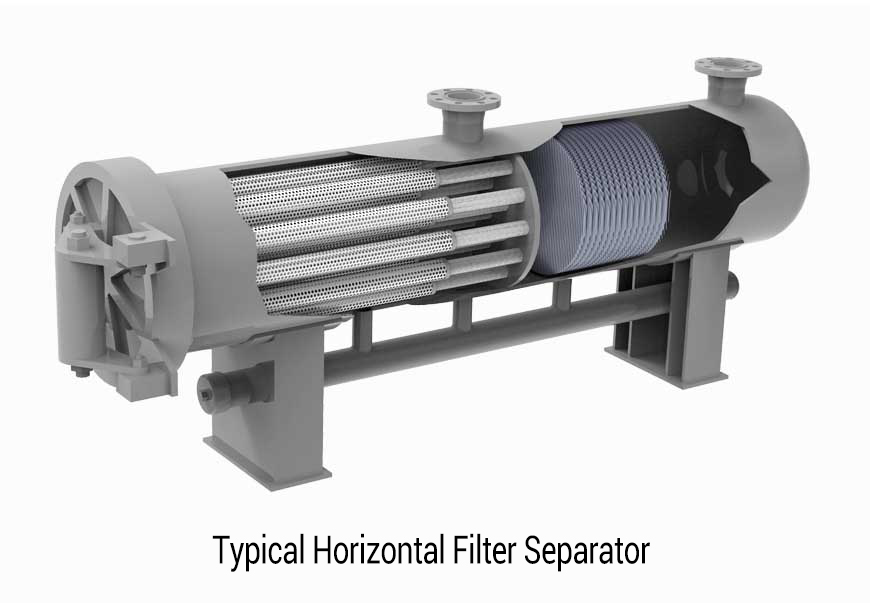

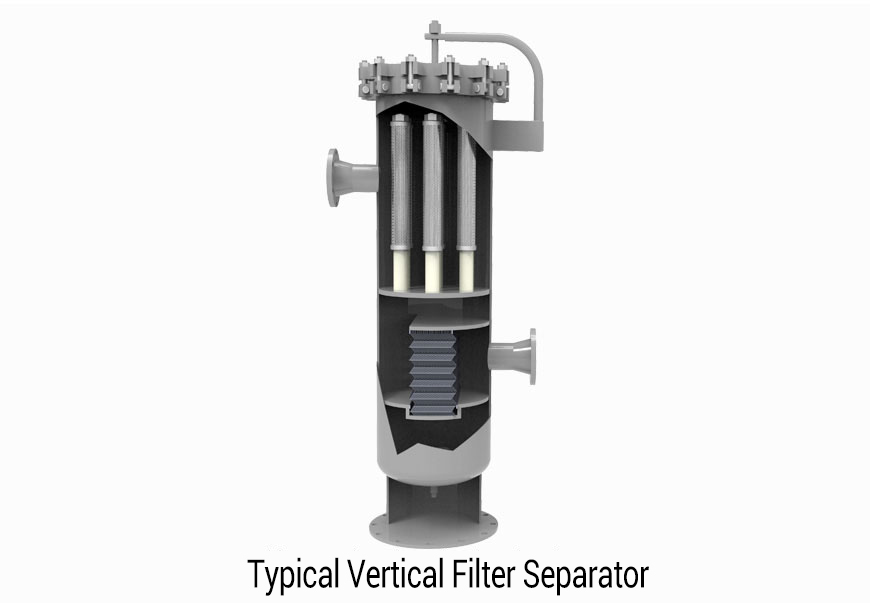

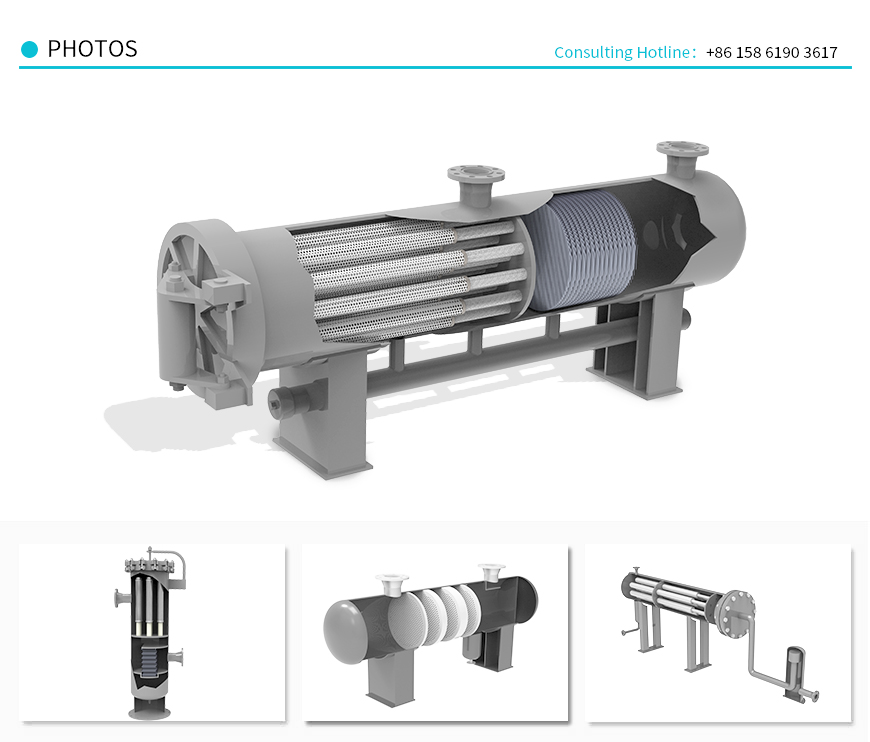

Natural gas filter separator is an important equipment for natural gas separation and dust removal. It is widely used in natural gas gathering and transportation pipelines and various gas stations. It is used to separate liquid, fine solid, dust and other particles in gas. Like other gas-liquid separators, gas filter separators can be horizontal or vertical; the most common type is horizontal. If there is a large amount of water in the incoming gas, the structure of the filter separator is designed to have a "guide" at the bottom of the separator, which is connected by two parallel pipes. Separation of hydrocarbons (oil) and water by precipitation requires a retention time of 3~5 minutes. The size of each part of the filter separator depends on the calculation and design of the manufacturer or engineering company.

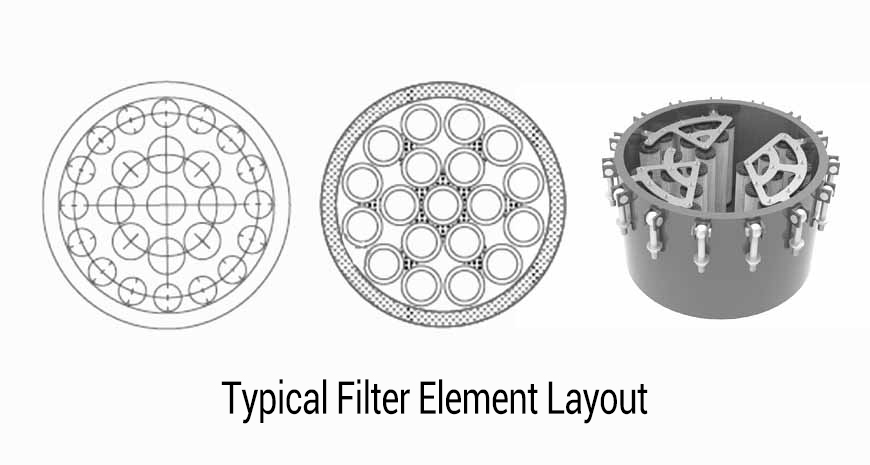

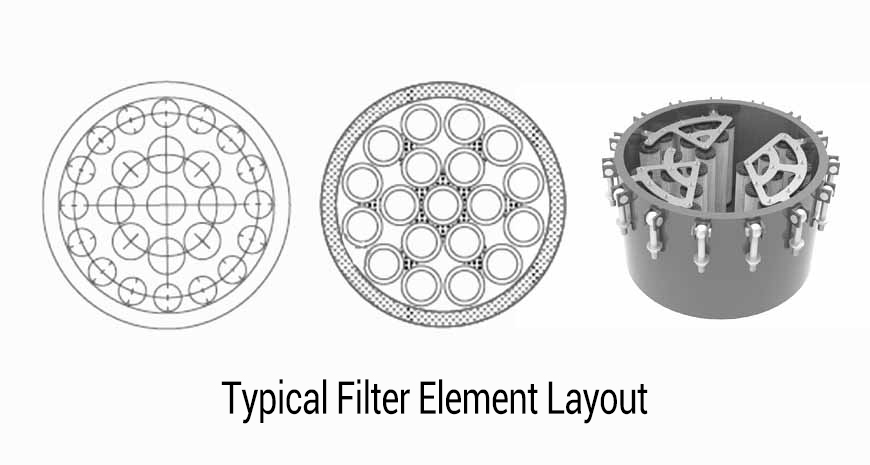

The natural gas filter separator is composed of coalescence filter and demister in its vessel. It usually has the function of quick opening and closing, which is used for the maintenance and replacement of filter.

When the droplet diameter is less than 3µm, filter separator and coalescence filter are required.

Natural gas filter separator is widely used in gas pipeline and gas treatment plant. For example, in an acid removal unit, the filter separator can capture liquid and concentrated hydrocarbon from the absorption tower after passing through the filter. In the process of gas treatment, sufficient import separators and filter separators are needed to prevent bubbles from chemical contamination. If the absorption tower is located downstream of the amine unit, glycol unit or compressor, a filter separator is required. In addition, the filter separator and coalescence filter are used to prevent the fine mist from entering the absorption tower.

The solid removal rate of the filter separator will be 100% when the solid particle size is 3µm and above;

The solid removal rate of the filter separator will be 99% when the solid particle size is 0.5-3µm;

The liquid removal rate of the filter separator will be 98%when the particle size is 8µm and above.

The efficiency of natural gas filter separator depends on particle size, distribution and liquid loading.

- Liquid / solid removal efficiency > 99%;

- High pressure drop;

- Sensitive to liquid and plug flow;

- Sensitive to solids and scaling.

Mainly used in oil, natural gas and petrochemical industries to complete liquid and solid removal of gases that has been separated by separator and desander and preliminarily demisted, as well as for the final purification of commercial gas.

Not recommended applications with:

- Heavy scaling, especially those with fibrous solid inclusion;

- Significant liquid content;

- Condition in which plug flow occurs.