Solid bed H2S scavengers unit is mainly used to remove hydrogen sulfide efficiently and safely from associated gas in oil field. The solid state H2S removal method is an ideal solution for gas processor to reduce hydrogen sulfide quantity and outlet pipeline, which can protect personnel and downstream equipment from hazardous and highly corrosive hydrogen sulfide.

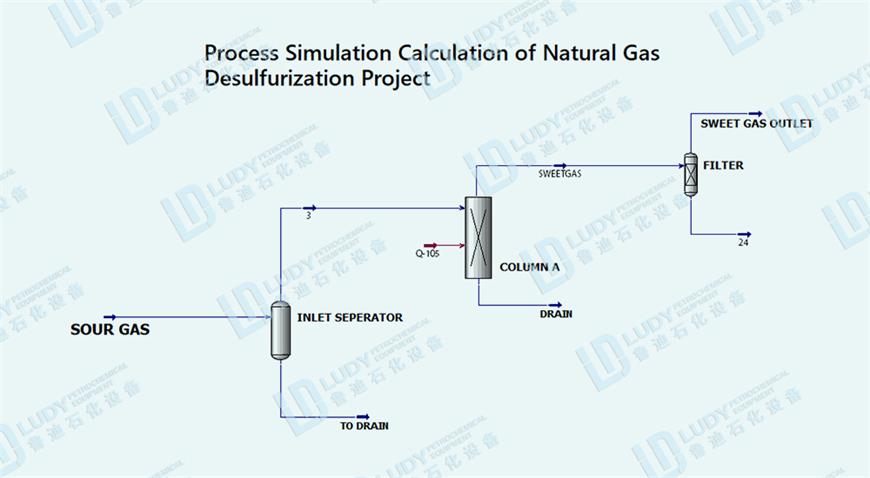

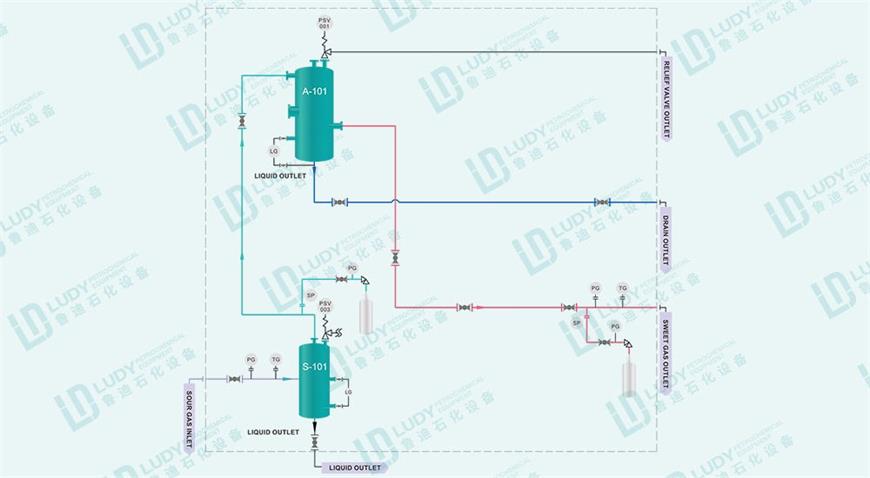

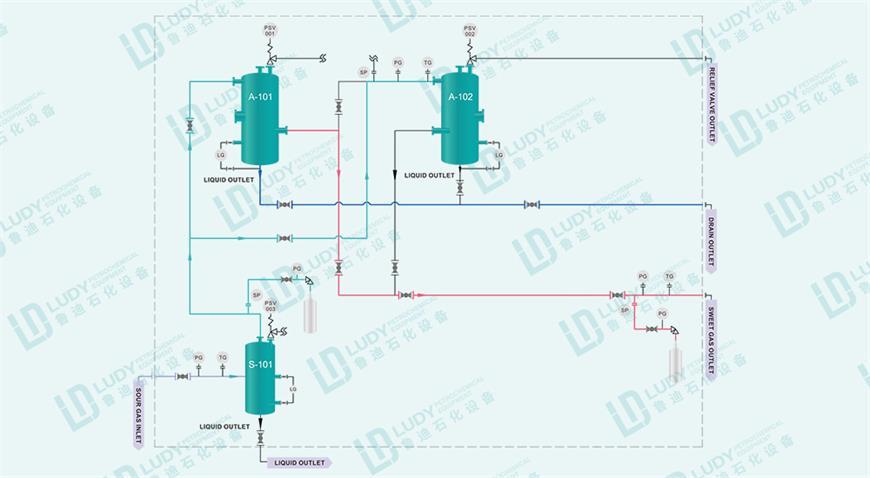

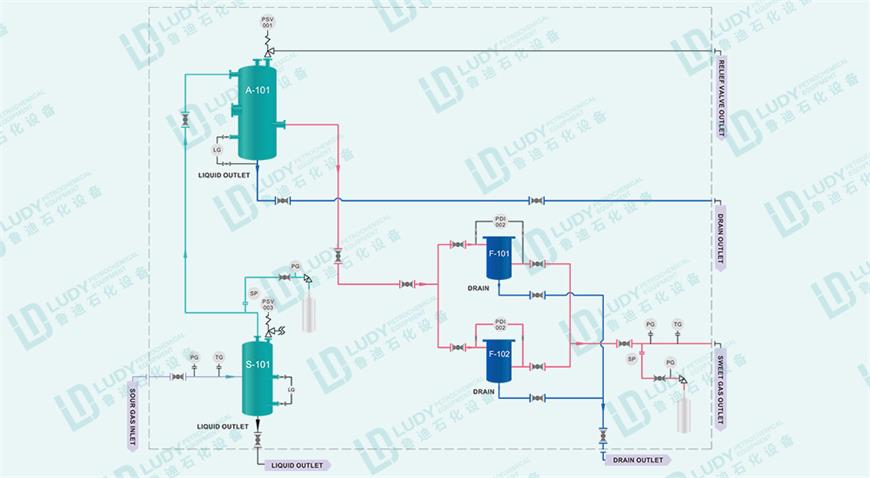

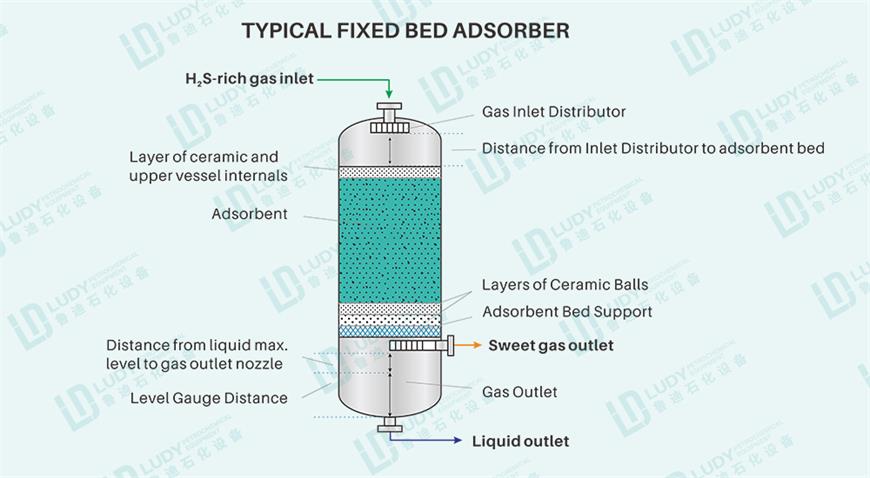

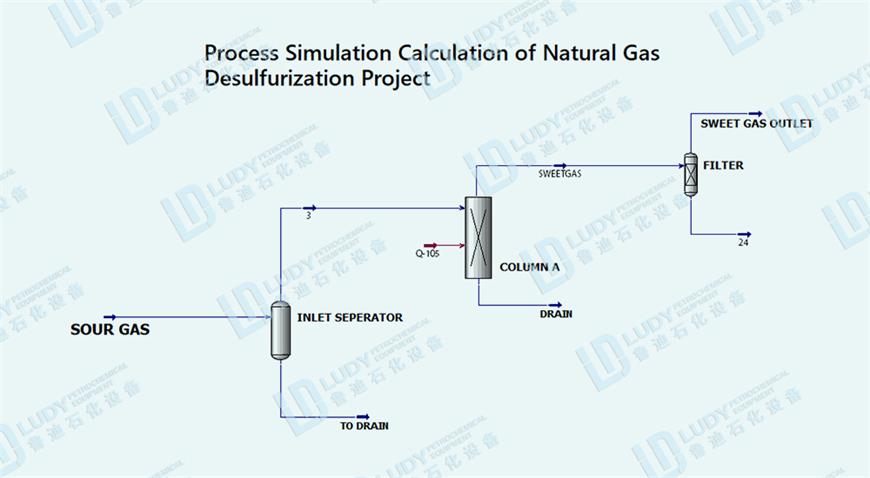

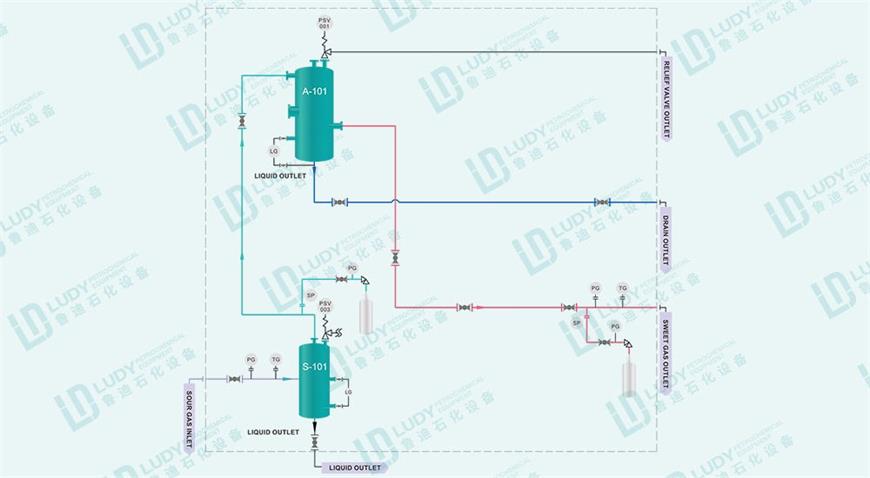

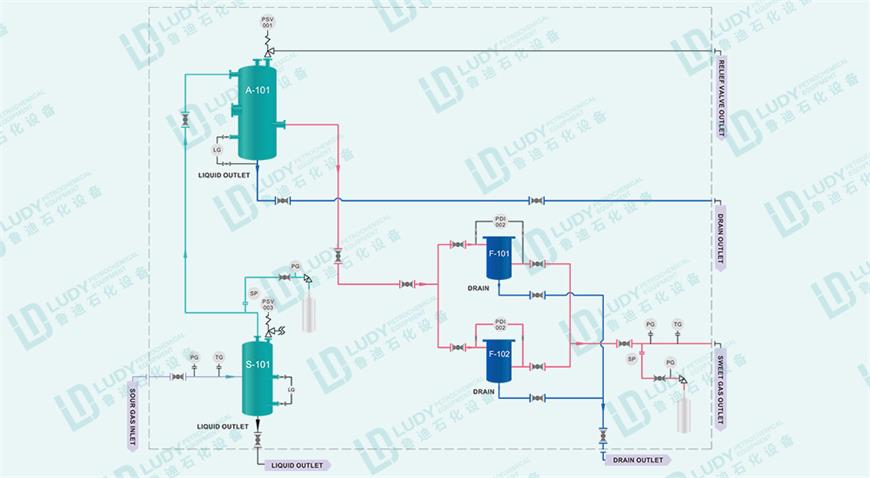

Different from H2S scavengers, solid scavengers are applied in batch mode. Sour gas (gas containing H2S) usually comes from the two-phase or three-phase separator in the well site and enters the solid-state removal unit. The unit consists of an inlet separator (vertical gas-liquid separator) and one or two desulfurization towers, including adsorbent bed, dry gas filter, instrument, sampling port and sampling device, operation platform, as well as those specified in Ludy's technical proposal or customer requirements Other system components. As shown in the chart provided by Ludy Petrochemical Equipment, all free liquids shall be removed from feed sour gas, as iron sponges require dry gas for quality H2S-removal performance. Liquid droplets present in the gas blocks porous structure of iron sponge slowing down its performance. Therefore, gas-liquid inlet separator is required.

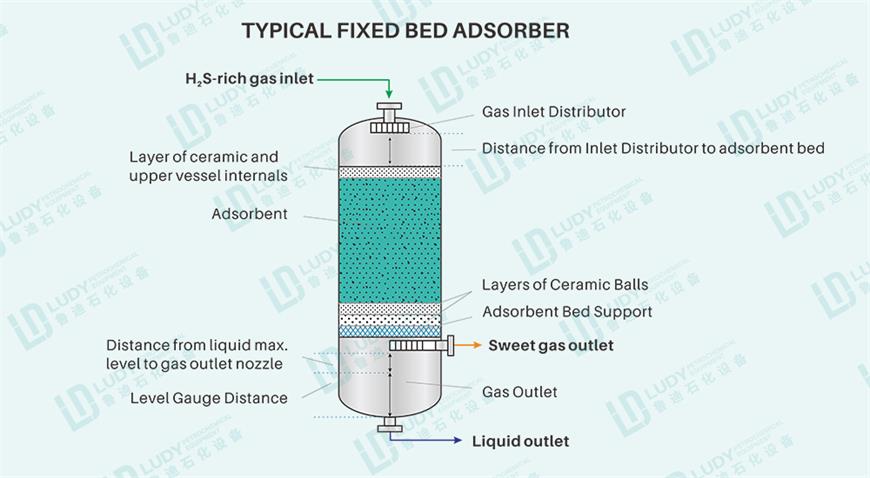

After gas-liquid separation, the sour gas enters the process tower from the top nozzle, and then flows downward. In the process tower, when the sour gas flows downward, hydrogen sulfide reacts with iron sponge to form iron sulfide and water. When H2S is trapped in the sponge bed, sweet gas ((H2S-free gas) flows out of the sponge bed. In the downstream, a dry gas filter can be used to filter small particles and iron oxide dust. According to the requirements of customers, Ludy can provide solid bed scavengers with and without dry gas filters respectively. The water generated after the reaction of H2S and ferric oxide accumulates at the bottom of the process tower and is discharged. Oxidation process gas sweetening system also includes pipeline valve, pressure relief valve, process instrument, sampling port and sampling system (optional) and other auxiliary components required by the project.

The level of control and automation depends on the customer's operating characteristics and budget. The equipment can be designed as manual operated valve, instrument with indication function and full automatic system. In a fully automated system, multiple transmitters, control valves, valves with actuators, electrical and signaling devices can be included, which may increase the total cost. As a flexible and experienced company, Ludy Petrochemical Equipment is able to provide manual and automatic control for gas sweetening system.

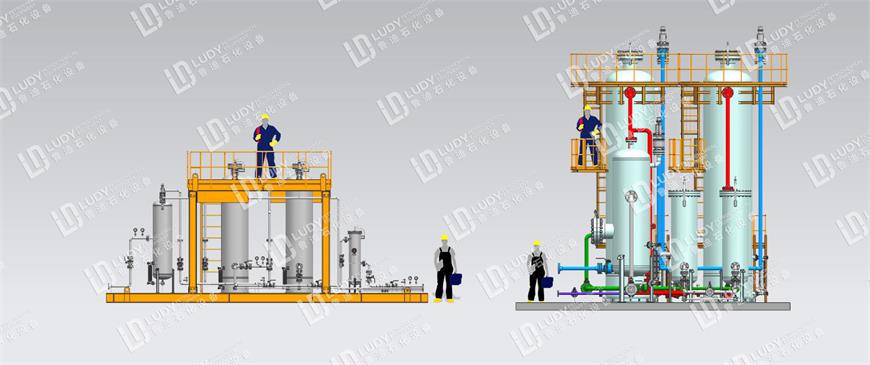

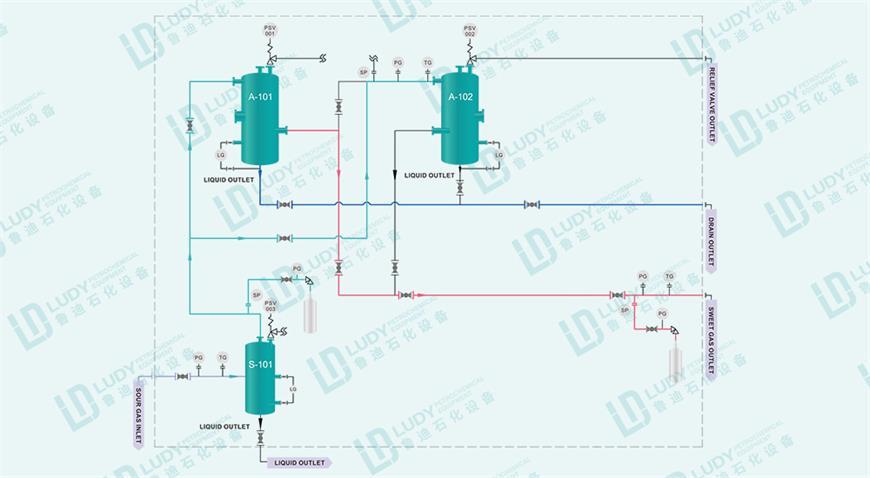

Two-tower Process

There are usually two towers, A and B, in iron sponge gas desulfurization units. In actual operation, tower A is the working tower for removing H2S, and Tower B is standby or in regeneration process. Another operation plan provided by Ludy is applying two towers work simultaneously. Two towers are used at the same time in case of high ppm content of H2S or high flowrate.

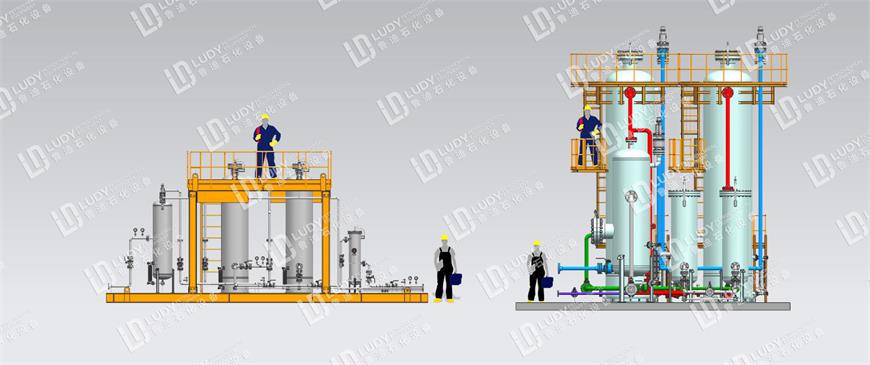

Single-tower Process

Iron sponge gas desulfurization units sometimes provides single tower according to customer requirements. Jiangsu Ludy Petrochemical Equipment offers both options with single tower and dual tower.

Sponge Bed Regeneration

Iron sponge regeneration rate can be up to about 50%. The regeneration is carried out by introducing air upward from the bottom of the tower to the top nozzle. Additional regeneration nozzles can be added in the configuration of the tower, or the nozzles of the pressure reducing valve can be used with proper design. Ludy will provide PFD and P&IDs to show system pipeline and configuration.

In practice, most companies usually replace spent sponge bed with new iron sponge, and safely disposing the spent sponge bed. Although the replacement process is simple, it still needs experienced and qualified professionals to handle it very carefully. Ludy will provide the necessary documents and manuals to properly dispose of spent sponge bed.

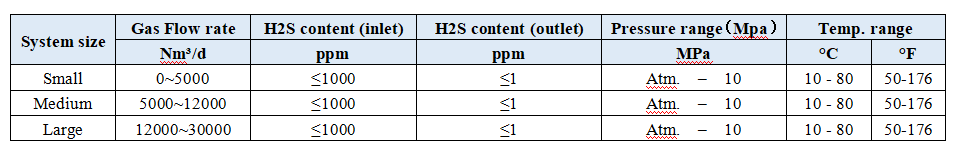

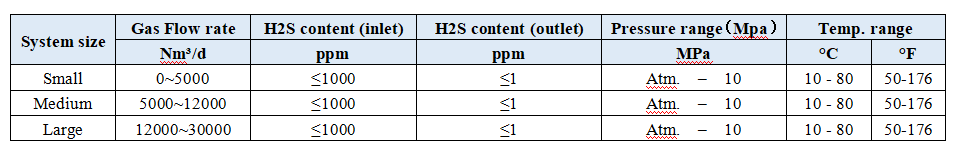

The size and configuration of the gas sweetening units by iron sponge process depends on several factors such as flow rate, operating pressure, H2S content, etc. Please send your requirements and field conditions to Ludy Petrochemical Equipment to obtain the most suitable and cost-effective solution for oilfield natural gas sweetening. You can also send the consultation online, and we will provide the data sheet for you to fill in.

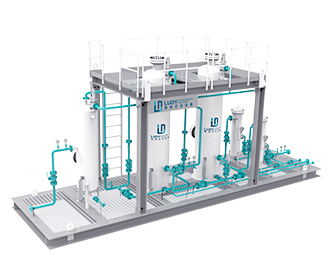

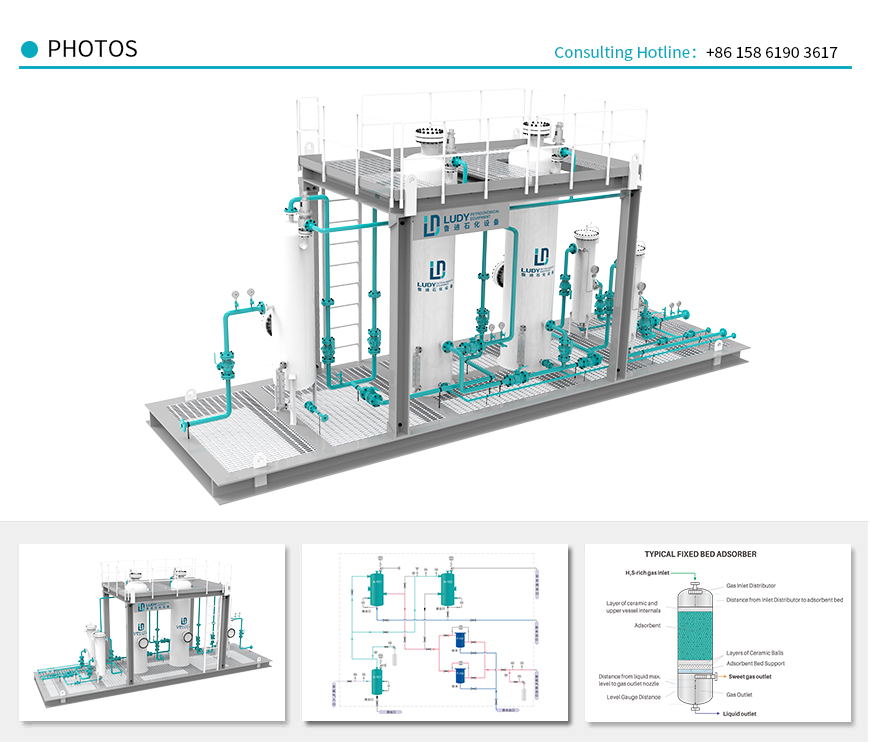

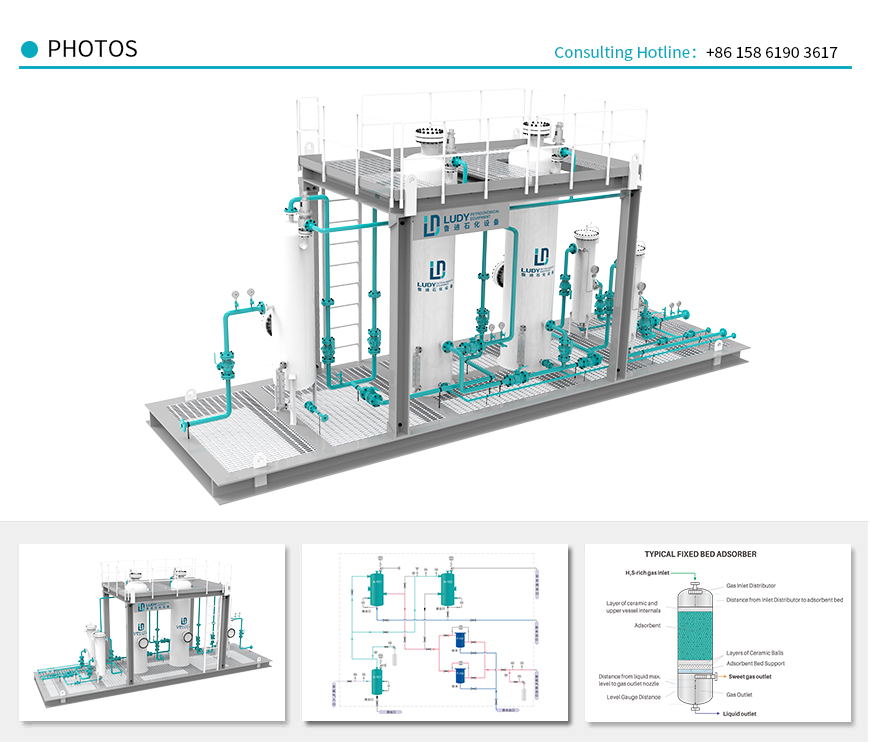

Ludy Petrochemical Equipment can independently design and manufacture Iron Sponge Gas Sweetening System in our production plant located in Dongtai City. The pipeline components of our professional production equipment are ANSI class and tested according to the specifications and standards. The construction of process equipment is suitable for H2S-containing environment.

- Reliable and stable for H2S removal

- Process guaranteed

- Easy to transport and installation (plug and play)

- Easy operation

- Optional gas sampling kits and gas analyzing systems

- Provide stable quality iron sponge

- Designed by qualified natural gas and chemical engineers

- Self-contained skid

- Digital control system

- ASME standard design or PED pressure vessel

- Conform to NACE MR0175/ISO 15156

- Cost-effective

- Fast delivery period

Important Notes:

- Given parameters are for reference only. In case of flow rate greater than 30000 Nm3/day, LUDY shall conduct study of the client’s requirements and provide suitable solution for greater flow rates. Please contact us for technical assistance.

- In case of H2S content in natural gas stream is between 1000 ppm and 10,000 ppm, LUDY will study provide process data, in order to deal with greater amounts of hydrogen sulfide to provide appropriate solutions.

- It is necessary to provide the natural gas flow rate, pressure, temperature and composition list of natural gas, including the content of hydrogen sulfide, mercaptan, sulfide, carbon dioxide and other substances, water dew point, hydrocarbon dew point and other process data for customized design.

- Current parameters are for reference only. Each Solid Bed Scavenger is designed and fabricated according to the requirements of the project. Please contact us for technical assistance.

Special process simulation software