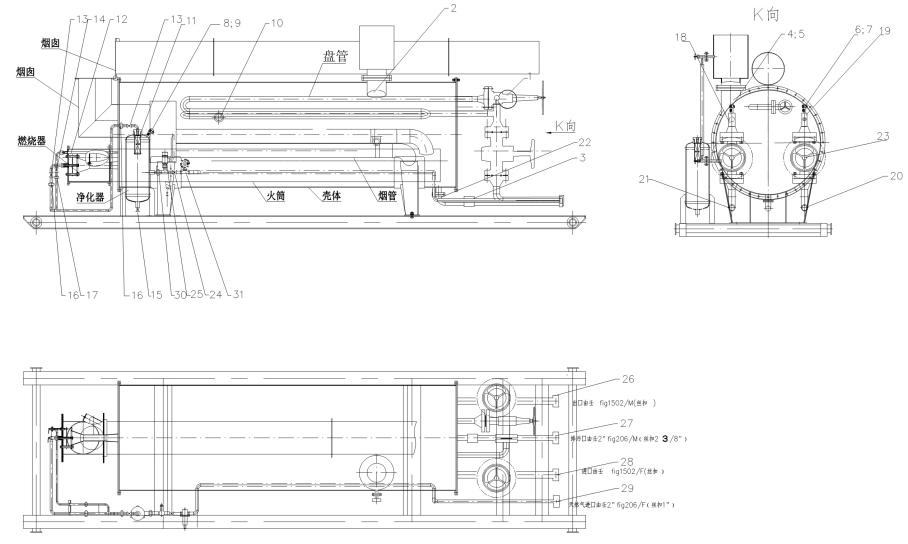

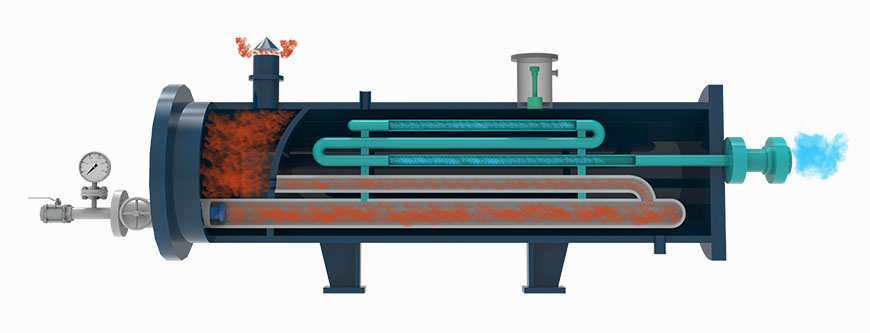

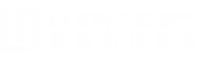

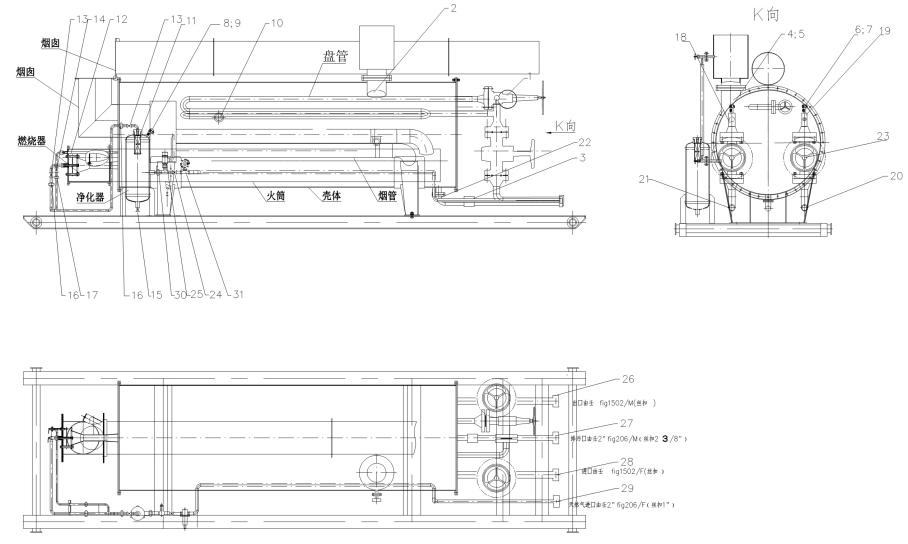

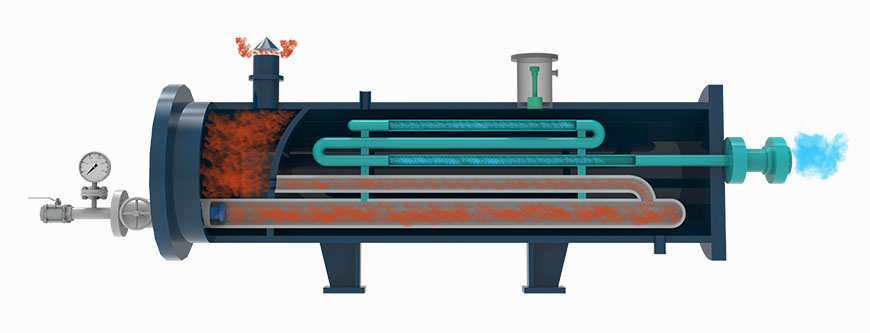

General description: Water Bath Heaters are designed to heat high pressure fluids and gas coming from the well or pipeline. Water bath heaters (water jacket furnace) used in oil and gas industry for heating medium of the pipeline to prepare for further technology needs. It also called indirect bath heater. The configuration of the heater may differ depending on the process application. Usually, the heater consists of main body with coil tubes, burner, fire-tube and flue stack. Sometimes skid may consider an expansion tank.

The main body refers to the basic vessel into which the fire-tubes and process coils are inserted from opposite ends. The burner ignites the fuel gas or fuel oil and blow it into fire-tube to heat the water in the vessel, and the hot water heats the medium in the coils such as crude oil or raw natural gas. The process coils are “bathing” in the water, and that’s why it’s called a water bath heater.

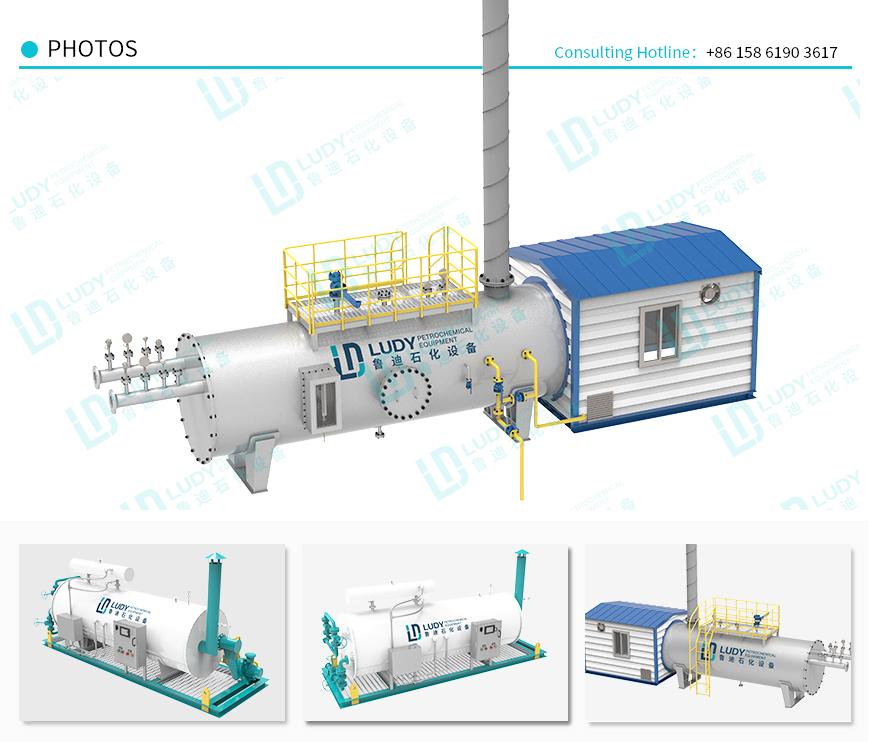

The heater shell has two saddle types supports, which is cuboid form and mounted on skid or special-designed bases. Outlet temperature may vary, but usually don’t exceed 86-88 °C.

- Sour medium;

- Heavy fouling medium;

- Salty medium;

- Specified kind of burner and fuel as per client requirements;

- Specified kind of control;

- Remote automation and control;

- Skid-mounted or trailer-mounted

- Heating of well fluids coming from choke manifold to prevent freezing/waxing of crude.

- Heating of raw natural gas before turbines

- Heating of sulfur gas in sulfur processing facilities

- Heating of chemicals to maintain proper temperature meeting process requirements.

- CE

- PED

- UL, Exp

- NACE MR0175

- API SPEC 12K

- API 6A, API 6D

- ASME Section VII, DIV 1

- ANSI B31.3 Class M (H2S)