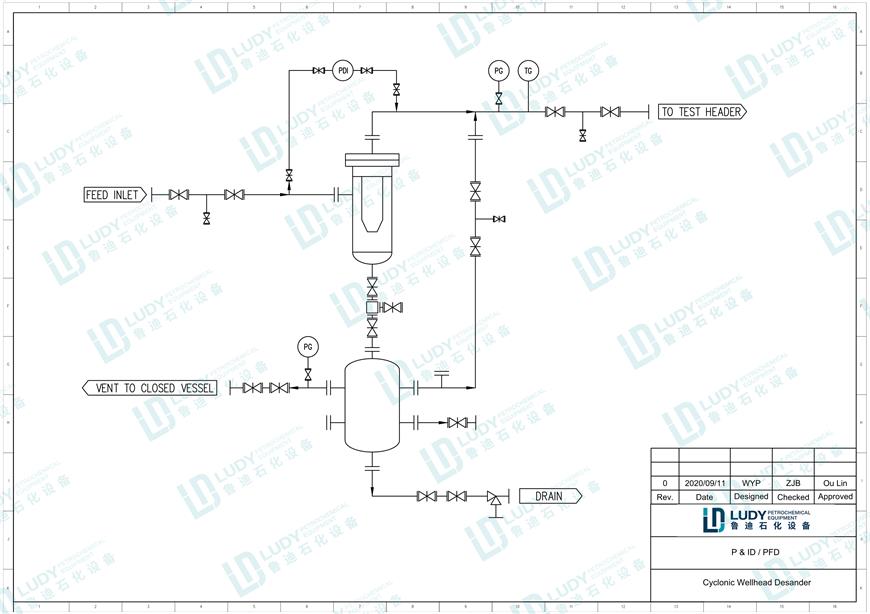

Wellhead cyclone desander is used to remove sand and solids from well fluid, which is an important device for desanding and downstream equipment. It uses centrifugal force (axial) and gravity to separate solids. Cyclone desander is the first surface desander in which gas and fluid comes into contact with surface equipment after wellhead X-mas tree.

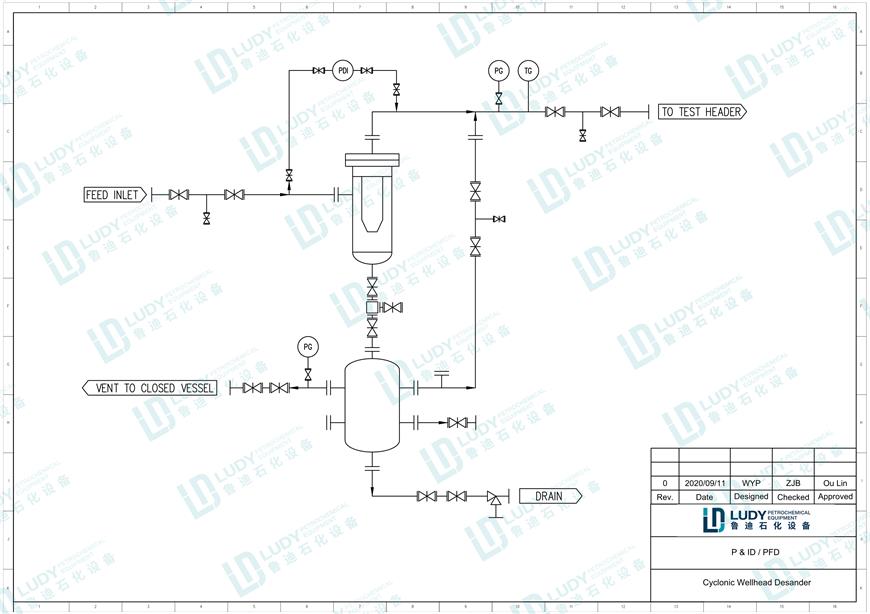

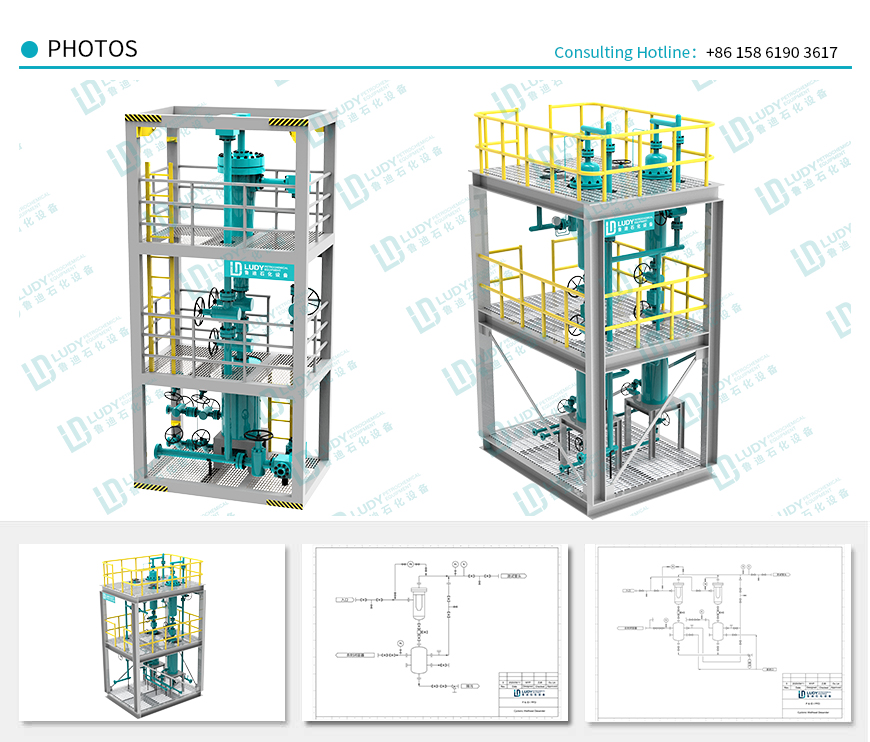

Wellhead cyclone desander is suitable for flow pressure between 1440psi and 15000psi. We design desander and accumulator according to ASME and API standards. The cyclone desander uses special swirl inserts made of stainless steel, special dual phase steel, tungsten carbide or other reinforced coatings to ensure longer service life. The desander inserts can be replaced after bing used up. The replacement depends on the operation cycle, operation time and the volatility of working medium. The construction materials of desander vessel, sand accumulator, pipeline and valve are usually carbon steel, and other special materials can be provided according to customer requirements and fluctuation of working medium. We conduct process calculations to ensure that the desander processes the given flow from minimum to maximum, and we perform mechanical calculations to ensure that the construction can withstand pressure and temperature under working and environmental conditions. Piping and instrumentation design ensures proper flow guidance and control. Desanders are usually equipped with instruments such as pressure gauges, thermometers, differential pressure gauges and other probes and transmitters according to customer requirements. Optional functions of the desander include sand probe and transmitter. Skid is made of carbon steel, which is convenient for transportation and installation of cyclone desander. Some offshore oilfield service companies may require DNV certification of skid-mounted equipment and additional requirements for space saving of desander steel structures. We ensure that the desander is manufactured in accordance with customer's requirements for process, space, working and environmental conditions, etc.

The wellhead cyclone desander and other sand and solid management equipment designed and manufactured by Ludy Petrochemical can guarantee high-efficiency mechanical performance and solid separation rate. Please feel free to contact us if you have any enquiry or technical assistance regarding cyclone desander.

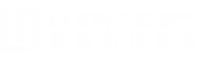

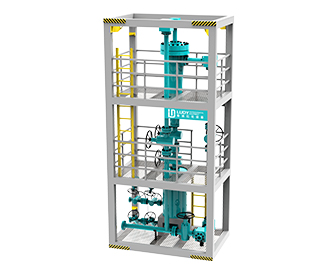

- Skid mounted to save space

- Lighter structure to meet quality performance

- Easy to operate and maintain

- Meet requirements of ASME / API / NACE / DNV

- Gas flow up to 100 MMCFD

- Liquid flow up to 10000 BOPD

- Design pressure up to 15000 psi

- Test pressure is 1.5 times of the working pressure

- Working temperature can be reduced to - 40℃

- Efficiency 94-97%