ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617Surge tank

-

Surge tank is a part of well test system, which is used to complete the secondary separation function after the well test separator, and to store the liquid and gas produced by the test separator. According to the requirements of well testing personnel, surge chamber can be divided into single chamber and dual chamber.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

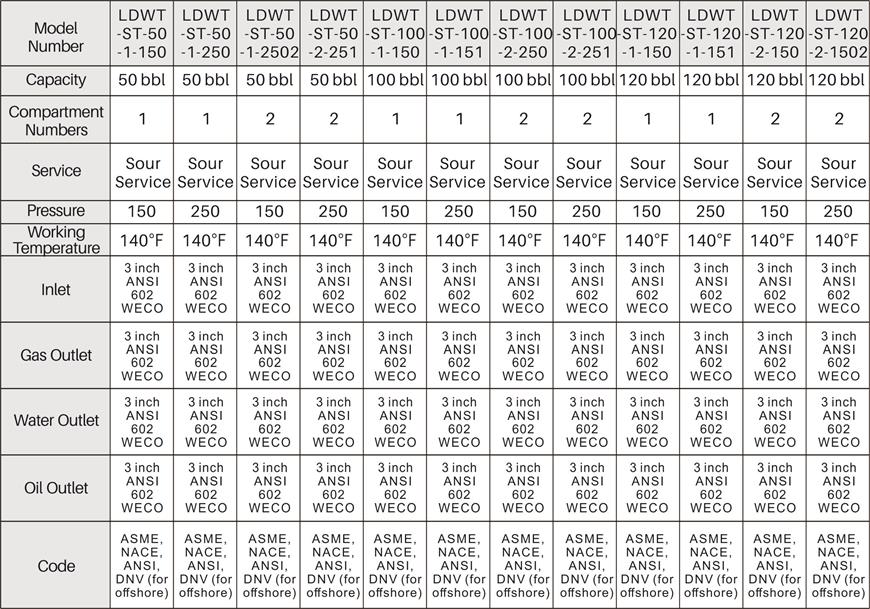

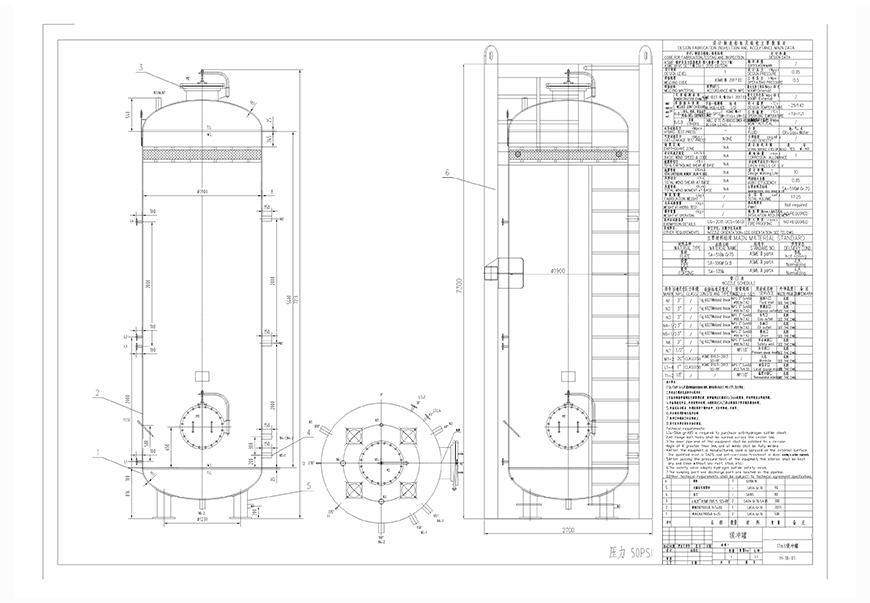

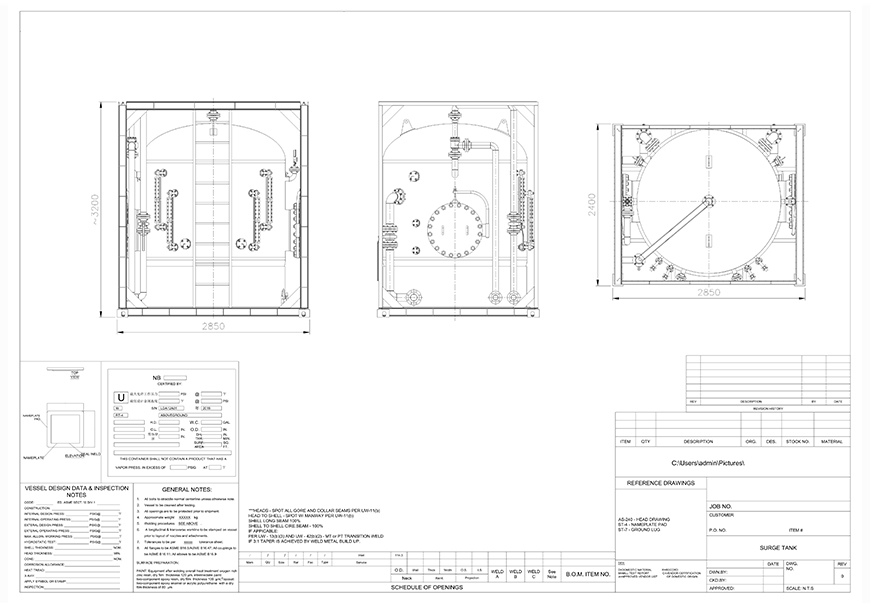

Surge tank is a part of well test system, which is used to complete the secondary separation function after the well test separator, and to store the liquid and gas produced by the test separator. According to the requirements of well testing personnel, surge chamber can be divided into single chamber and dual chamber. In well testing, the pressure regulating vessel is usually composed of pressure vessel (usually sour/acid equipment), sight glass (level indicator), pressure and temperature indicator, pressure relief valve, level alarm system and skid. Some customers may require pressure control valves as part of the skid valve and piping. In some areas with high wax content, the vessel of surge tank is designed with steam heating coil to ensure proper temperature for further oil transportation. The frame (skid frame) of surge tank is required to be designed according to DNV standard and approved by this agency in some operation areas.

The surge tank is filled with liquid from the test separator and further transported to the metering tank or directly to the flare for further processing. Different from the gas of the test separator, the gas from the pressure regulating vessel is usually treated through the exhaust pipe, which is installed far away from the operator to avoid casualties.

On offshore platforms, the pressure regulating tank replaces the atmospheric pressure gauge tank and shall meet the requirements of DNV and local certification. The pressure vessel is designed according to ASME standard with ANSI flange connection.

- For well testing

- Easy to clean up

- Hydraulic backflow

Surge tank is a part of well test system, which is used to complete the secondary separation function after the well test separator, and to store the liquid and gas produced by the test separator.

On some offshore platforms, the pressure regulating tank replaces the atmospheric pressure gauge tank and shall meet the requirements of DNV and local certification. The pressure vessel is designed according to ASME standard with ANSI flange connection.

Leave a message

* is required

- *