Leading Industry R&D and Production Level

Ludy Petrochemical Equipment has been committed to the production and development of pressure vessel equipment, such as separator, ground test equipment,

in order to achieve maximum efficiency and precision products. High quality equipment with high cost performance can be customized.

-

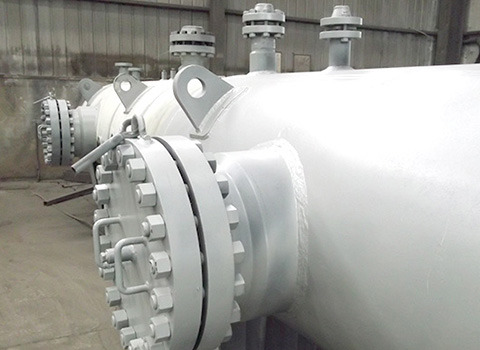

Three-phase separator

Jiangsu Ludy has many years of manufacturing and practical experience in the production of three-phase separators, with first-class technology and excellent quality. Our three-phase separator has been widely used in Xinjiang, Inner Mongolia, Shaanxi, Tianjin, Hebei and other major oil and gas fields, and has been highly praised by users. According to user's requirement, we can design the separator horizontally or vertically. Not only do we have the product with comprehensive self-control and superior performance, but also provide perfect after-sales service and favorable quotation. Please feel free to contact us.

-

Liquid-liquid two-phase separator

In the production process of oil and gas wells, oil and water will be mixed together by external force, in order to be extracted with the state of water-in-oil and oil-in-water. This requires the use of a separator to separate it, oil as an output to the next stage of production, water to be discarded or refilled, or treated as domestic water for oilfield construction sites, etc.

-

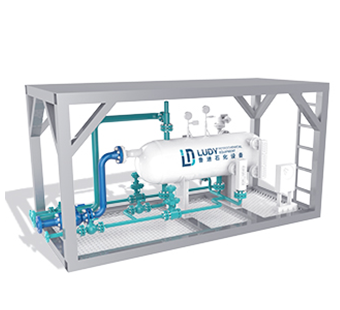

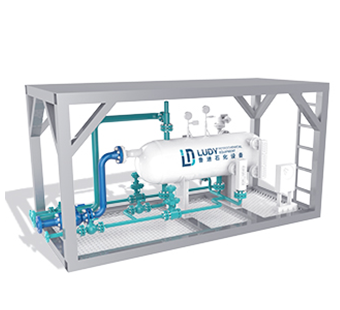

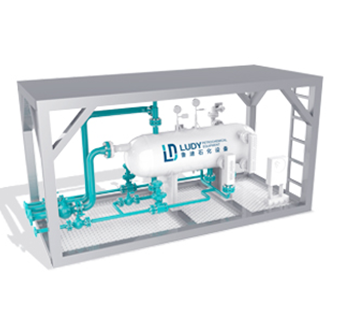

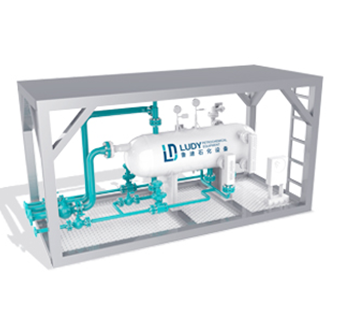

3-phase Separation and Metering Skid with Heating

3-phase Separation and Metering Skid with Heating is designed to increase temperature and perform three-phase separation of the well fluids. It is widely applied in domestic oil & gas fields, conducting pressure-reducing (by choke valve), heating (water bath heating), and separation (3-phase separation). Usually, it is designed to handle 300,000 Nm3 of natural gas per day.

-

Gas-liquid two-phase separator

Used for gas-liquid separation. For the oil-gas mixture extracted from crude oil or natural gas well, when only gas and liquid are required to be separated, a gas-liquid two-phase separator is needed. The separator can be horizontal or vertical, the former is more conducive to the treatment of a large amount of liquid, and the latter is more conducive to the treatment of a large amount of gas. At the same time, the horizontal type is preferred when the height of installation space is limited, and the vertical type is preferred when horizontal dimensions are limited.

LUDY Petrochemical Equipment (Jiangsu) Co., Ltd

This is a modern high-tech environmental protection technology enterprise integrating R&D, design, production, sales, and service.

-

Productive & sales type enterprises with professional production capacity

In the possession of welding equipment, cutting equipment, lifting equipment, welding material drying box, plate rolling machine, radiography room and other mechanical processing equipment; Be able to independently complete machining, welding, testing, instrumentation, installation and commissioning of mechanical and electrical equipment and other processes;

With all kinds of professional quality inspection and testing equipment.

-

Professional technical engineer team

Our professional technical engineer team of petroleum equipment is able to provide customers with one-to-one design according to their requirements and use environment.

With extensive design experience in a variety of complex environments domestic and abroad.

-

Persistent process innovation while focusing on independent R&D

Continuous improvement of oilfield testing and separation equipment technology to meet the latest requirements domestic and abroad;

5% of the sales is invested annually into R&D of new equipment to strive to be realistic and innovative.

-

Quality assurance

Rely on strong R&D strength and integrate the world's cutting-edge technology concept so as to quickly respond to the changing needs of customers;

Perfect quality inspection system, to provide customers with advanced, reliable, safe, high-quality complete sets of engineering facilities and product solutions.

-

Rich experience in production and sales of petroleum and petrochemical equipment

Long-term partner of oil leading industry with years of pressure vessel equipment production experience;

With the experience of exporting to many countries around the world and has won the reputation from foreign customers.

News

Wellhead high-pressure cyclone desander for Sichuan

Recently, the high-pressure cyclone desander manufactured by Ludy for Sichuan customers has been successfully installed and put into use at the customer's site.

- Wellhead high-pressure cyclone desander for Sichuan 2020-12-29

- Three-phase separation metering device for Shanxi Natural Gas Field 2020-12-29

- Regular domestic customer once again ordered 300,000m3 natural gas three-phase separator 2020-12-29

- Gas filter separator of common separator in gas pipeline 2020-04-13

High Automation

To Provide You with Customized Equipment

GB standard three-phase separator for Egypt

GB standard three-phase separator for Egypt

Skid-mounted three-phase separator for Pakistan

Skid-mounted three-phase separator for Pakistan

300,000 m3 three-phase separator for Puyang

300,000 m3 three-phase separator for Puyang