ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617-

Details

-

Contact

What is LNG?

LNG, namely liquefied natural gas, is a gas that is cooled to -260℉(-162℃) and converted into liquid. When natural gas exists in liquid form, it takes up about 1/600 the space of gaseous state, which makes transportation more efficient and economical.

How is natural gas liquefied?

Natural gas is converted to liquid in a liquefaction plant or station. The LNG station mainly performs three processes:

1. Pre-processing

Dust and plug flow (water and condensate) are removed along with mercury (Hg). These contaminants can cause corrosion and freezing problems, especially in aluminum heat exchangers.

2. Acid gas removal and dehydration

Carbon dioxide (CO2) and hydrogen sulfide (H2S) is absorbed and removed from natural gas by amine absorber (acid gas removal, abbreviated as AGR), while adsorbent is used to remove water. These impurities are removed so that ice does not form during the subsequent liquefaction process.

3. Heavy hydrocarbon separation and liquefaction

Prior to liquefaction, heavy hydrocarbons (C5+) are removed by fractionation. As shown in the schematic diagram of the liquefaction process, natural gas is pre-cooled with propane to approximately - 31℉(-35℃).

.png)

After pre-cooling, the natural gas passes through the pipeline loop of the main cryogenic heat exchanger (MCHE), where the natural gas is liquefied by mixed refrigerant (MR) and under-cooled to between -238℉(-150℃) and -260℉(-162℃). MR shall also be pre-cooled and then separated in high-pressure separator. In MCHE, steam and liquid flows through different tubular loops, where they are further cooled, liquefied and under-cooled.

The pressure of these two under-cooled air streams is reduced and further reducing their temperature. As the mixed refrigerant vaporizes on the shell side of MCHE and flows downward, it provides refrigeration for the liquefaction and under-cooling of natural gas. LNG end-flash occurs at the outlet of MCHE and in the storage tank receiving LNG, generating flash gas and boil-off gas to supplement the fuel gas required for the compression cycle driven primarily by propane and MR gas turbines.

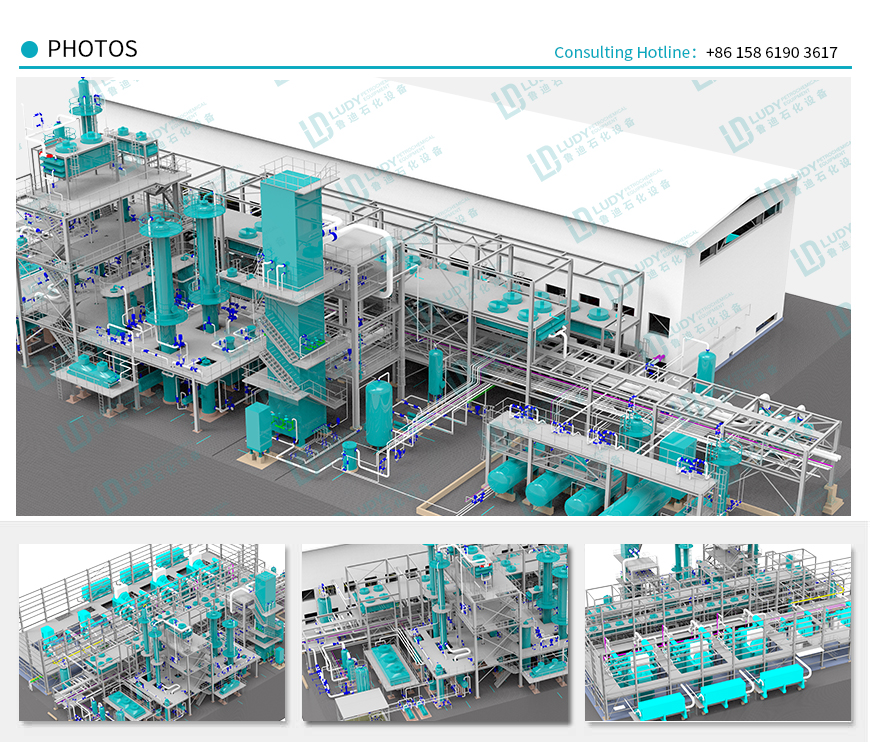

The process of natural gas liquefaction plant basically includes pretreatment (purification), liquefaction, storage, loading and auxiliary systems, etc. The main process flow includes natural gas purification and liquefaction process. The process and control composition of general liquefaction plant is as follows:

- Feed gas filtration

- Feed gas acid- gas removal

- Feed gas drying & mercury removal

- Liquefaction and heavy-hydrocarbon removal

- Refrigeration

- Refrigerant supplement

- LNG storage & loading

- BOG gas

- Heavy-hydrocarbon storage & fuel gas

- Utilities & auxiliary facilities

- Computer Data Acquisition & Monitoring System (SCADA)

- Safety Instrumented Systems (SIS)

- Electrical System

- Nitrogen Generation System (PSA Nitrogen Generation)

- Heating System

- Instrument Air System

- Water Supply System (circulating cooling water unit, desalinated water unit)

- Fire Water System

- Fire & Gas System (FGS)

- Video Surveillance System (CCTV)

- Flare System

Applicable working conditions and application fields of natural gas liquefaction plant

1. Applicable working conditions:

- Applicable air volume: 1×104 Nm3/d → 500×104 Nm3/d

- LNG temperature can be as low as -162 ℃

- Applicable air source pressure: normal pressure →10 MPa

2. Application fields:

- Associated gas liquefaction in oil & gas fields

- Shale gas liquefaction

- CBM liquefaction

- Coal-to-Natural gas Liquefaction

- Pipeline natural gas liquefaction

- Coke-oven gas liquefaction

How to store LNG?

- LNG is stored in fully sealed tanks with a capacity of 160,000 cubic meters. The pressure of the LNG tank is kept slightly higher than one atmospheric pressure.

- The fully sealed system has two tanks, the internal tank for storing products and the external tank for preventing leakage.

- The internal shell is made of a special nickel alloy, which can resist low temperature, while the external shell is pre-stressed concrete with reinforced plates and roof.

- Each tank is insulated to keep LNG at about -256℉(-162℃) and features a sophisticated automatic protection system to monitor the tank level, pressure, temperature and any potential leakage.

How is LNG transported?

LNG is transported in special double-hulled vessels. The most common types of holds are the membranous hull-supported hold and the self-supporting B-type spherical cargo tanks (Moss). Each type of cargo hold is sealed with a cryogenic material that is insulated and can reduce the vaporization rate of cargo to less than 0.15% per day. It takes about 14-16 hours for LNG to be unloaded from the wharf to the terminal storage tank. Throughout the process, the temperature of LNG is maintained at -160°C. Since 1964, LNG has been commercially transported by ships, and no LNG losses were recorded for 88,000 cargoes or 176,000 voyages by the end of 2016.

外形图纸1.jpg)

外形图纸2.jpg)

外形图纸3.jpg)

外形图纸4.jpg)

Leave a message

* is required

- *