ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617A Mini- mol. sieve Gas Dehydration Unit for CNG & LNG services

Home » A Mini- mol. sieve Gas Dehydration Unit for CNG & LNG servicesA Mini- mol. sieve Gas Dehydration Unit for CNG & LNG services

-

LUDY Petrochemical Equipment designs and fabricates a CNG- and mini LNG-service molecular sieve gas dehydration units for the surface oil & gas projects. A compact and modular mol. sieve gas dehydration unit is designed to remove or reduce water content from the natural gas stream.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

LUDY Petrochemical Equipment designs and fabricates a CNG- and mini LNG-service molecular sieve gas dehydration units for the surface oil & gas projects. A compact and modular mol. sieve gas dehydration unit is designed to remove or reduce water content from the natural gas stream. The gas dehydration process is very essential for natural gas processing, liquefaction, NGL recovery, CNG, LNG, or pipeline transport.

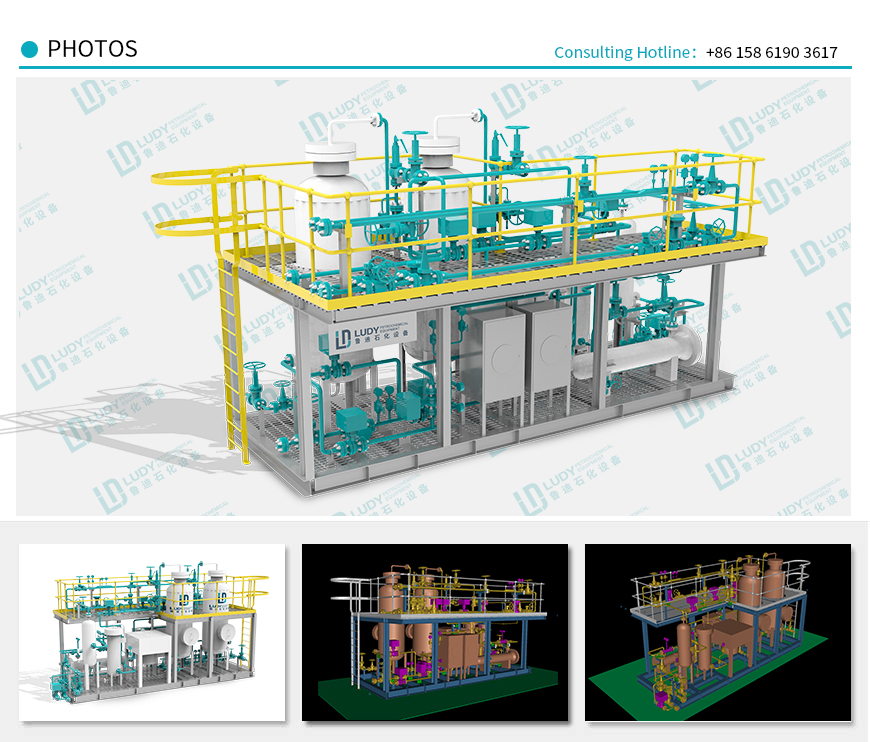

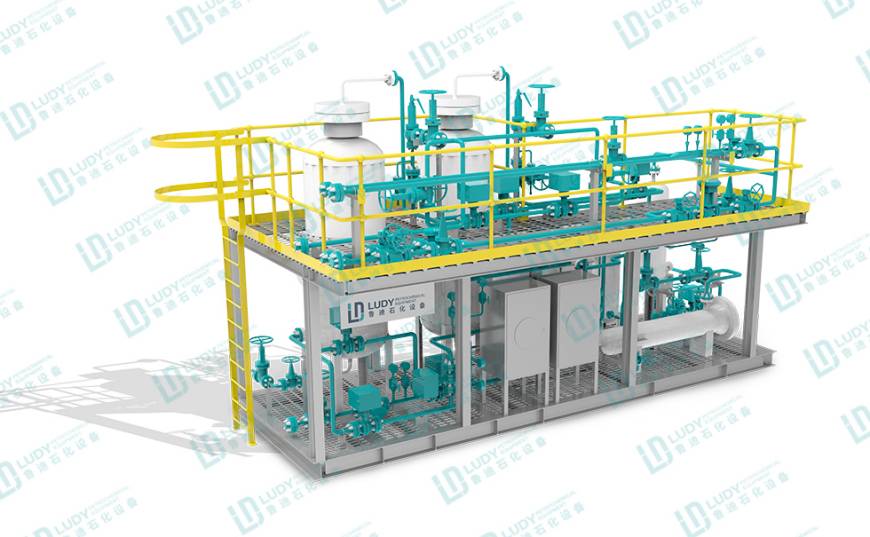

The natural gas dehydration units can be designed for high pressure and high flow rates. It has adsorber columns (A/B or A/B/C), filter, gas-liquid separator, heater, air-cooled unit, piping, instruments, and electrical. All items are mounted on the skid for fast-track installation, fast start-up, and mobilization from one field to another after a certain period of operation. LUDY Petrochemical Equipment designs the skid-mounted packages considering transport limits and requirements of the project. We focus on reducing installation works at the site, and increasing start-up efficiency. Our modular units are designed to meet the process (工艺)and performance requirements, following international, domestic, and commonly used codes & standards in the oil & gas industry.

.jpg)

.jpg)

.jpg)

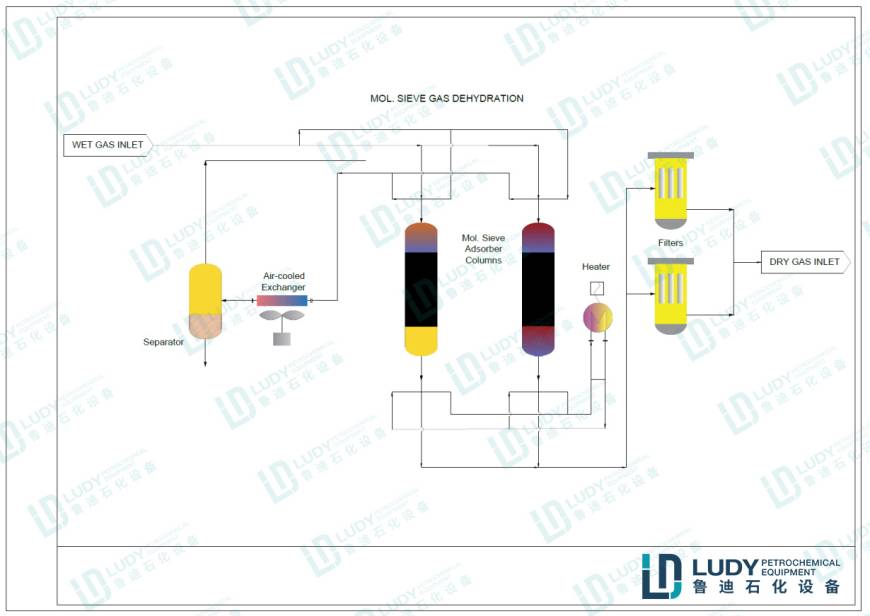

Wet natural gas enters adsorbers, which contain solid desiccants, mol. sieves. Adsorbents capture water and the dry gas is discharged to the filters, which remove any dust or particles that dry gas may carry after leaving adsorbed. Depending on the project and selection of the configuration, a Two-column or Three-column configuration could be selected for process design. Columns work interchangeably A/B or A/B/C, performing operating/regeneration/cooling modes. As the adsorbent captures water, the water shall be removed from the adsorbents for repeating the cycle. After the adsorbent bed performed its operating function, actuated valves switch to the regeneration mode, supplying hot gas to the adsorbent for regeneration. Depending on the size of the gas dehydration unit, either an electric heater or a direct-fired heater is selected, both performing heating purposes. Hot air enters the column, the adsorbent release the water, and then hot gas is discharged to the air-cooler and gas-liquid separator to recover the natural gas and drain the separated water.

> Skid-mounted, modular design;

> Electric or direct-fired heater;

> High-level of automation;

> Can be designed for harsh environmental conditions;

> Heat tracing and insulation;

> Control & Automation Equipment;

> Safety devices;

> High-pressure application;

> Customization as per the client’s requirements;

> Complies with international and domestic standards.

> Flow rate: up to 50 MMSCFD;

> Design pressure: up to 1440 psi (99) bar or higher;

> Design temperature: as per project;

> Construction Materials: as per project specification;

> Working modes: continuous, 8/8/8 or 12/12;

> Control & Automation: PLC control / DCS control

> Codes & Standards: GB, HG / ASME, ISO, IEC, API, NFPA, AGA

Feel free to contact us for more information and technical support. LUDY Petrochemical Equipment offers a wide range of products for natural gas treatment and processing, such as the glycol gas dehydration unit, amine gas sweetening units, and mol. sieve units, mercury removal units, CNG systems, mini- and mid-sized LNG plants, NGL recovery, LPG production, Condensate Stabilization, and many other solutions for oil & gas, power & energy industries.

Leave a message

* is required

- *