ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

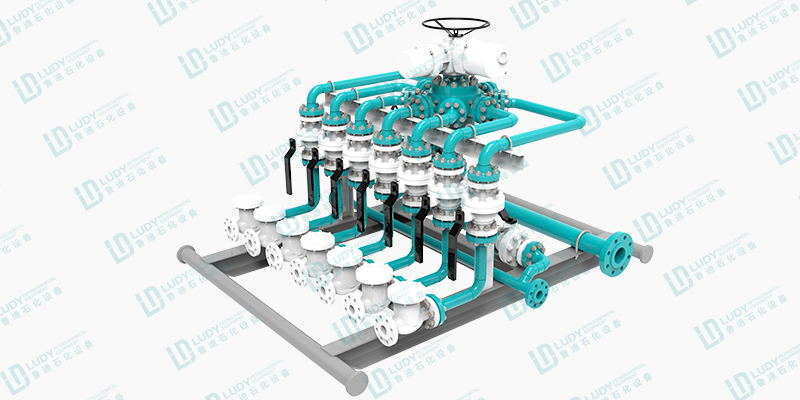

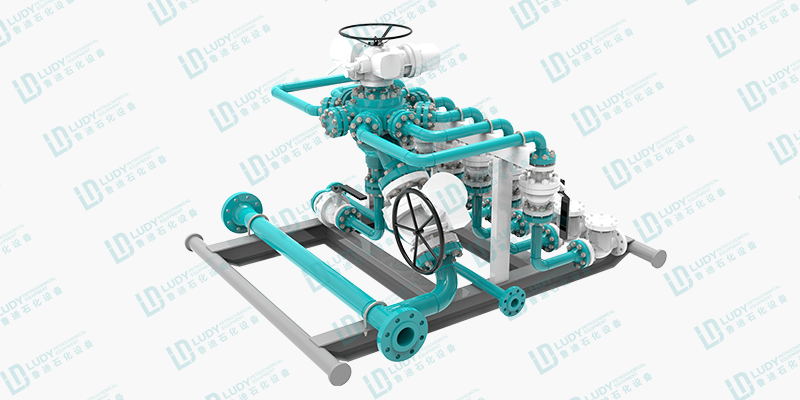

+86 158 6190 3617Multiport selector valve

-

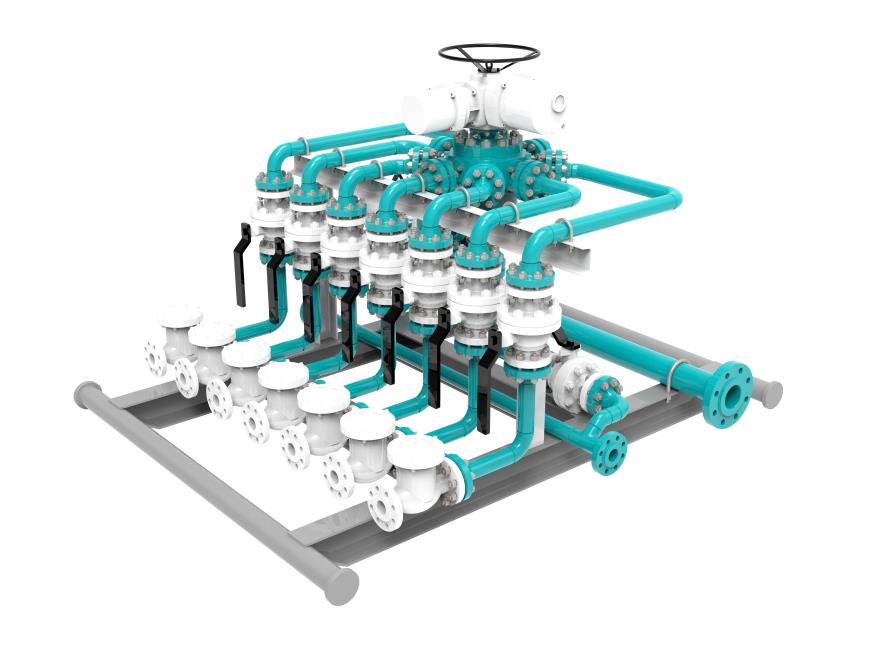

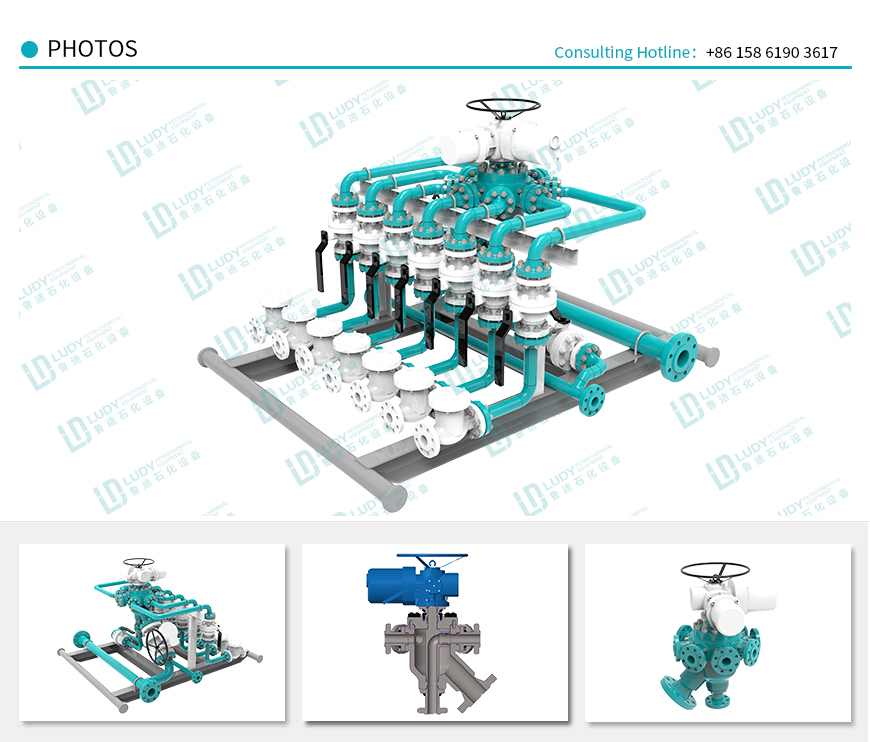

Multiport selector valve (MSV) is a cost-effective, efficient and compact engineering device, which can improve production management and well optimization. MSV allows fluid to be transferred from a single pipeline to a test outlet or sampling device.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

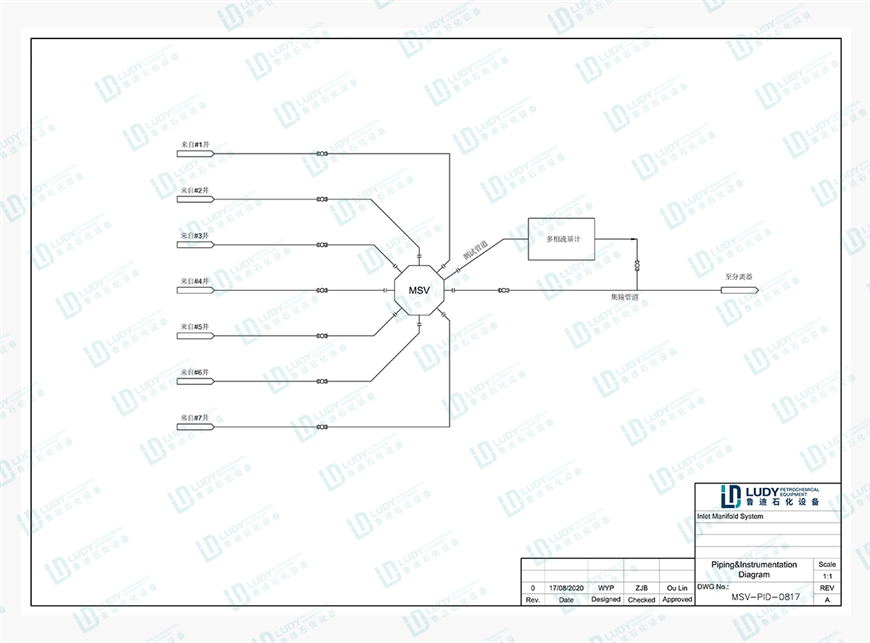

Multiport selector valve (MSV) is a cost-effective, efficient and compact engineering device, which can improve production management and well optimization. MSV allows fluid to be transferred from a single pipeline to a test outlet or sampling device. A single MSV can pass through up to seven pipelines simultaneously. When one inlet is isolated, fluids from the other six inlets are combined into a single outlet.

This unique fluid selector valve can be used either as a stand-alone device or in combination with multiphase flow meters in various oil, gas or process applications. MSV can also be used for water injection to enhanced oil recovery (EOR). It can be used to simplify control in environments where size, weight and reliability are key factors. MSV reduces the installation, operation, and maintenance costs throughout the life cycle of a well testing system.

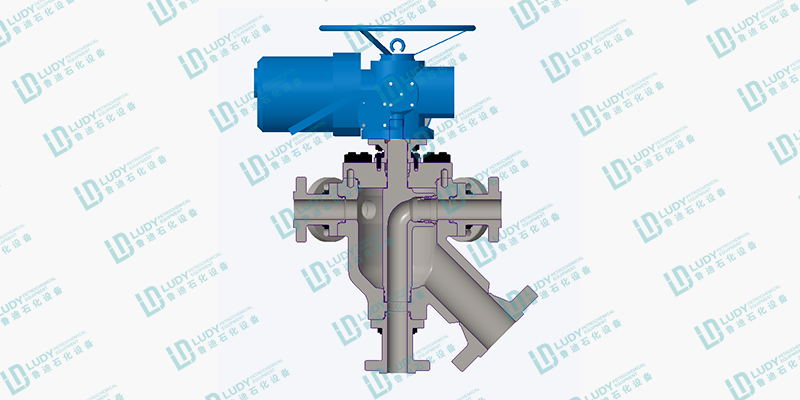

A single MSV can be used as a replacement for a complete 2-way or 3-way valve in the test well selection system, acting as a compact manifold and providing a simple and safe way to select the multiphase flow you wish to connect to or test the well of the separator.

However, most of the common MSV at present adopt a soft sealing structure. Although the structure of the MSV is simple, because of its use of soft material as a sealing pair, it is not resistant to wear and has a very short life. The sealing surface of the MSV produced by Jiangsu Ludy can be overlaid and spray welded, and the hardness can reach HRC60 degree or higher. The sealing surface is scratch-resistant, wear-resistant, erosion-resistant and corrosion-resistant. It is easy to operate and does not require to change the sealing material, which is suitable for various oilfield environments.

- Compact design of MSV reduces installation and maintenance costs

- Self-cleaning function prevents the accumulation of scale, paraffin and other deposits

- Fewer sealing surfaces to reduce leakage

- Provide manual or automatic operation and add automation at any time

- With 8 air inlets, which can connect up to 8 pipelines at a time

- With field adjustable seal and stainless steel scraper, which can extend the service life

- Especially suitable for multiphase flowmeters

- Remote control and status indication can be realized through two line communication

- Reduce the number of isolation valves in the production / test manifold

- Working temperature range: -20℉ ~ +392℉ (- 29℃~+200℃)

- Suitable for a variety of surface treatments in all operating environments

Model | 2×4 | 3×6 | 4×8 | 4×10 | 6×16 |

Inlet size (in.) | 300/600 | 300/600/900/1500 | 300/600/900/1500 | 900/1500 | 300/600/900 |

Test outlet (in.) | 2 | 3 | 4 | 4 | 6 |

Group output (in.) | 2 | 3 | 4 | 4 | 6 |

Working pressure (psi) | 4 | 6 | 8 | 10 | 16 |

Max. static test group differential pressure (psi) | 1000/1480 | 1000/1480/2225/3333 | 1000/1480/2225/3333 | 2225/3333 | 1000/1480/2225 |

Max. static group test differential pressure (psi) | 1200 | 1000 | 800 | 1000 | 700 |

Max. dynamic seat differential pressure (psi) | 900 | 700 | 600 | 1000 | 700 |

Standard max. Temp. (F) | 600 | 500 | 400 | 700 | 500 |

Test outlet Cv | 225 | 225 | 225 | 225 | 225 |

Group outlet Cv | 67 | 151 | 270 | 217 | 491 |

Weight | 262 | 594 | 1040 | 1292 | 3658 |

- Save fixed investment cost

- Save integral skid mounting space

- Save operation labor cost

- Save maintenance cost

- Save installation time, construction and maintenance costs

- Realize automatic control

- Compact design, small occupied area and less ecological impact

- No concrete foundation required

- Ensure repeatability and accuracy of plug position without slipping

- Position tolerance < 0.5o

- The fuselage geometry is optimized to prevent corrosion

- Independent position feedback

MSV is designed to provide economical test automation with simple, direct installation and control functions.

Leave a message

* is required

- *