ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617Gas Booster Skid with 3-phase Separation and Heating

Home » Gas Booster Skid with 3-phase Separation and HeatingGas Booster Skid with 3-phase Separation and Heating

-

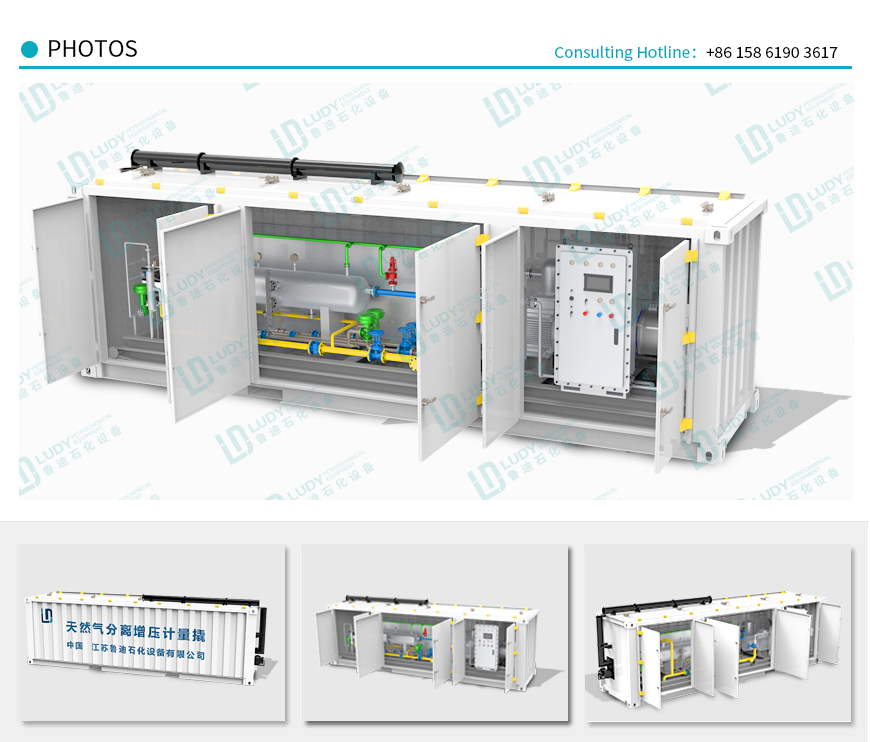

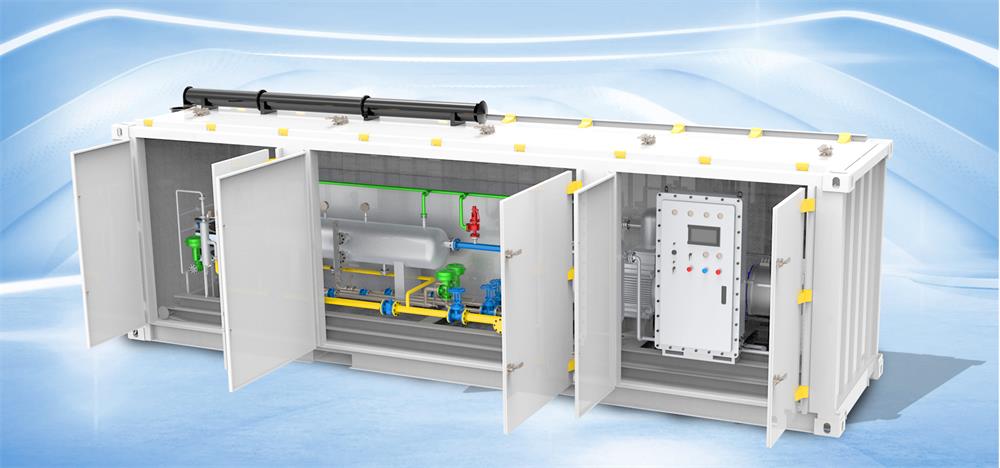

The Gas Booster Skid with 3-phase separation and heating is designed to heat up the fluids, conduct three-phase separation (oil, gas, water), measure flowrate of each phase and boost the gas pressure to transport to the further station or CNG or mini-LNG application.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

The Gas Booster Skid with 3-phase separation and heating consists of heating (indirect principle), 3-phase separation (momentum, gravity), and a gas compressor with control and automation systems. All instrumentation and electrical components are explosion-proof with water & dust protection. The current modular booster skid is designed to heat up the fluids, conduct three-phase separation (oil, gas, water), measure the flow rate of each phase, and boost the gas pressure to transport to the further station or CNG application. It increases the natural gas pressure from 0.5-2 MPa up to 6 MPa. The Gas Booster Skid is modular, skid-mounted, and easy to transport and mobilization. The modular unit requires less site works for installation, commissioning, and mobilization. Feel free to contact our company for more information, technical assistance, price, and customization.

> Skid-mounted/Modular;

> Integrated Supervisory and Data Acquisition System;

> Control & Automation Panel with its components;

> Container-type with optional features such as heating, venting, heat tracing;

> Sour and standard services;

> Customized as per the project requirements;

> Fast delivery period and cost-effective;

> Natural gas field, CNG, mini- or mid-sized LNG application;

> ASME, API, ISO, IEC, NFPA, NACE and other relevant standard.

> Working medium: natural gas, oil, water;

> Gas flow rate: 100 000 – 500 000 Nm3/h

> Design pressure: 9.9 MPa (1440 psi)

> Compressor inlet pressure: 0.3-3 MPa

> Compressor discharge pressure: 4-6 MPa

> Working Mode: continuous

> The package can be customized as per the project requirements

Leave a message

* is required

- *