ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617Pressure vessel

-

Pressure vessel is a vessel designed to contain gas or liquid at the pressure that differ greatly from ambient pressure. We conduct high-quality surface treatment and use high-quality coating materials to ensure the durability of pressure vessels during use.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

Pressure vessel is a vessel designed to contain gas or liquid at the pressure that differ greatly from ambient pressure.

Pressure vessels can be dangerous and have had fatal accidents in their development and operation. Therefore, the design, manufacture and operation of pressure vessels are supervised and managed by engineering departments supported by legislation. Therefore, the definition of pressure vessel varies from country to country.

The design parameters include maximum safe working pressure and temperature, safety factor, corrosion allowance and minimum design temperature (brittle fracture). Structural testing uses non-destructive testing, such as ultrasonic testing, radiographic testing and pressure testing. Hydrostatic testing is preferred because it is safer and less energy is released if a fracture occurs during the test (the volume of water does not increase rapidly during rapid depressurization, unlike gases such as air that explode).

In most countries, vessels over a certain size and pressure must be constructed according to formal specifications. In the United States, it is ASME Boiler and Pressure Vessel Code (BPVC). In Europe, it is the European Pressure Equipment Directive (PED). The information on this page is only valid in ASME. These vessels also require the authorized inspector to sign each new vessel constructed and each vessel needs to have a nameplate with relevant information, such as maximum allowable working pressure, maximum temperature, minimum design metal temperature, manufacturer, date, its registration number (through National Committee) and the official seal of ASME Pressure Vessel (U stamp). The nameplate makes the vessel traceable and officially becomes the ASME Code vessel.

One particular application is the manned pressure vessel, which is subject to stricter safety regulations.

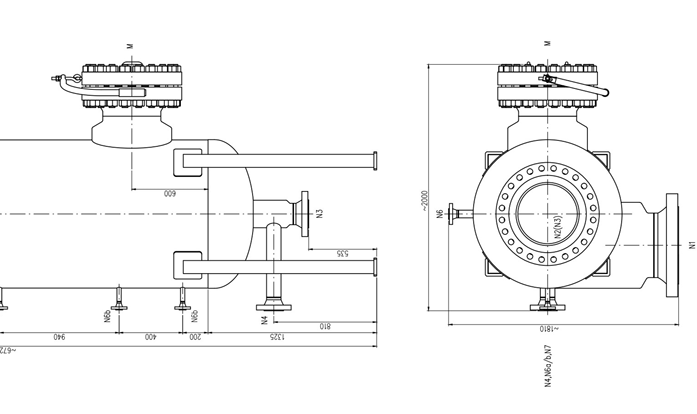

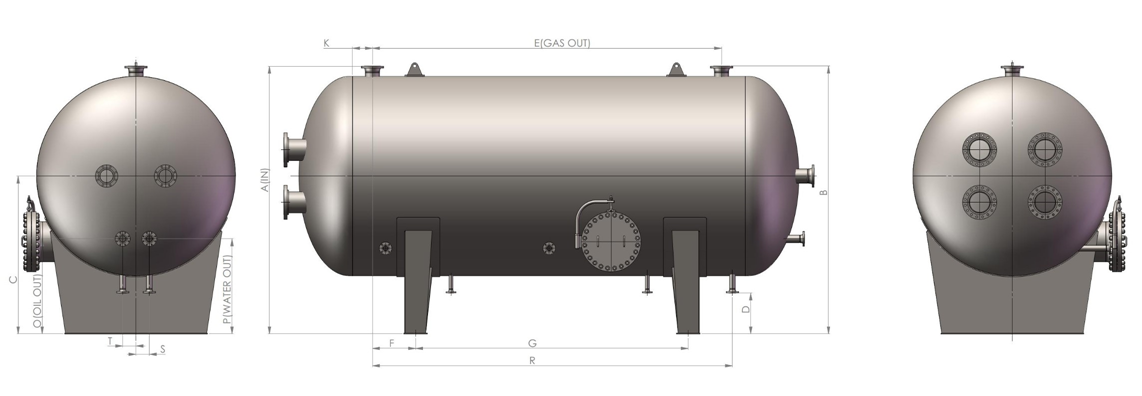

In theory, pressure vessels can be of any shape, but they are usually made up of spheres, cylinders and cones. A common design is a cylinder with an end cap called a head. The head shape is usually hemispherical or disc-shaped (hyperboloid / circular). Historically, more complex shapes are more difficult to analyze for safe operation and are generally more difficult to construct.

The strength of a spherical pressure vessel is theoretically about twice that of a cylindrical pressure vessel with the same wall thickness, so it is an ideal shape to maintain internal pressure. However, spherical containers are difficult to manufacture and thus more expensive. Therefore, most pressure vessels are cylindrical with 2:1 semi-elliptical heads or end covers at both ends. A small pressure vessel is assembled by a pipe and two covers. For cylindrical vessels with a diameter of no more than 600mm (24in. NPs), seamless pipe can be used as the outer shell to avoid inspection and testing problems, primarily non-destructive testing of long welds when required. The disadvantage of these vessels is that the larger the diameter, the higher the cost. For example, the most economical 1000L (35cubic feet), 250bar (3600psi) pressure vessel may be 91.44cm (36in.) in diameter, 1.7018m (67in.) in length, including a 2:1 semi-elliptical dome end cap.

Many pressure vessels are made of steel. To make a cylindrical or spherical pressure vessel, rolled or forged parts must be welded together. Unless special precautions are taken, certain mechanical properties of steel obtained by rolling or forging may be adversely affected by welding. In addition to adequate mechanical strength, current standards require the use of steel with high impact resistance, especially for vessels used at low temperatures. In applications where carbon steel is vulnerable to corrosion, special corrosion resistant materials should also be used.

General standards and specifications

- GB 150

- GB 151

- GB50251-2015

- GB/T20972

- ASME Section VIII

- BS 5500

- API 510

- CE/PED

- NACE MR 0175 / ISO 15156

- GOST

- other applicable standards

Working Pressure

The typical cylindrical high-pressure cylinder used for permanent gases (such as air, oxygen, nitrogen, hydrogen, argon, helium, etc., that do not liquefy at storage pressure) is a seamless steel vessel made by hot pressing and rolling.

In Europe, the standard operating pressure for industrial, technical, diving, and medical cylinders was only 150bar (2200psi) until about 1950. Since 1975, the standard pressure is 200bar (2900psi). Firefighters need lightweight cylinders to move around in limited space; since 1995, cylinders with a working pressure of 300bar (4400psi) have been used (the first use of pure steel).

Since pressure vessels are designed according to a certain pressure, there are usually safety valves or pressure relief valves to ensure that the pressure will not be exceeded during operation.

Jiangsu Ludy designs and manufactures pressure vessels and complete modules and systems, among which pressure vessels are one of the main equipment. Our complete set of modules and systems mainly include:

- Test separator

- Two-phase separator

- Three-phase separator

- Horizontal separator

- Vertical separator

- Cyclone separator

- Gas-liquid separator

- Liquid-liquid separator

- Separator with liquid package

- Production separator

- Chemical injection skid

- Surge tank

- Filter separator

- Dry gas filter

- Gas regulating skid

- H2S-removal unit

- Gas dehydration unit

- NGL recovery unit

- Cryogenic equipment

- Heat treatment device

- Crude oil heater

- Natural gas heater

- Inlet separator (scrubber)

- many other devices

Jiangsu Ludy is mainly engaged in the design and manufacture of pressure vessels for the oil and gas industry. We ensure the high-quality performance and mechanical performance, and complies with domestic and international codes and standards. Our team consists of senior engineers in mechanical and pressure vessel manufacturing. We have strict quality control standards to ensure timely delivery and meet project requirements. We conduct high-quality surface treatment and use high-quality coating materials to ensure the durability of pressure vessels during use. For technical support and the quotation, please feel free to contact Jiangsu Ludy. We will be committed to your service, and guarantee you the high-quality assurance, competitive prices and accurate delivery time.

Application

- Oil and gas industry

- Petrochemical industry

- Natural gas treatment

- Crude oil refining

- H2S-removal unit

- Gas dehydration unit

- NGL recovery

- Cryogenic equipment

- LNG plant

- Chemical industry

- Pharmaceutical industry

- Food processing

- other industrial applications

Leave a message

* is required

- *