ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617Cyclone desander

-

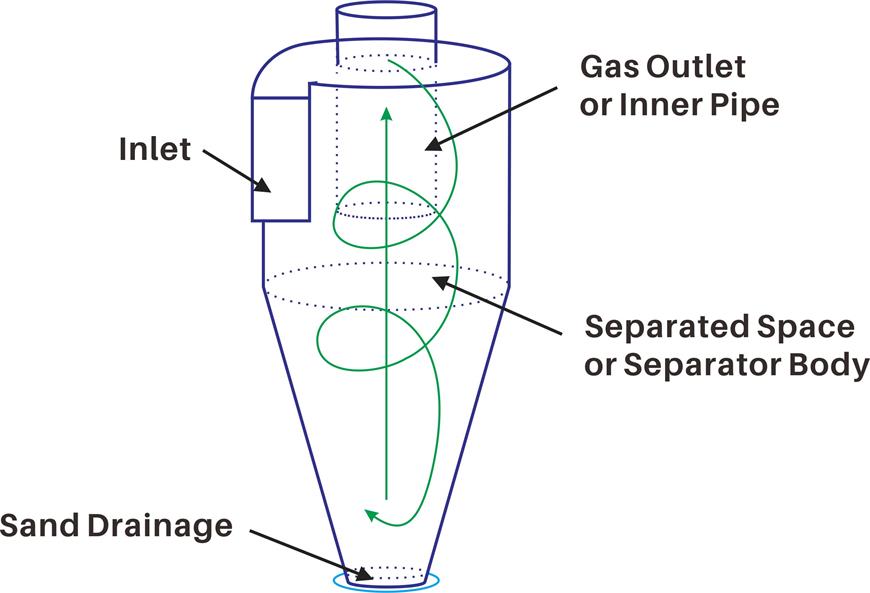

Cyclone desander, also known as cyclone dust collector, is used to separate dust particles from air flow by centrifugal force generated by rotating air flow, which is used to separate dust particles with particle size greater than 5-10µm. It has a history of more than 100 years in industry.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

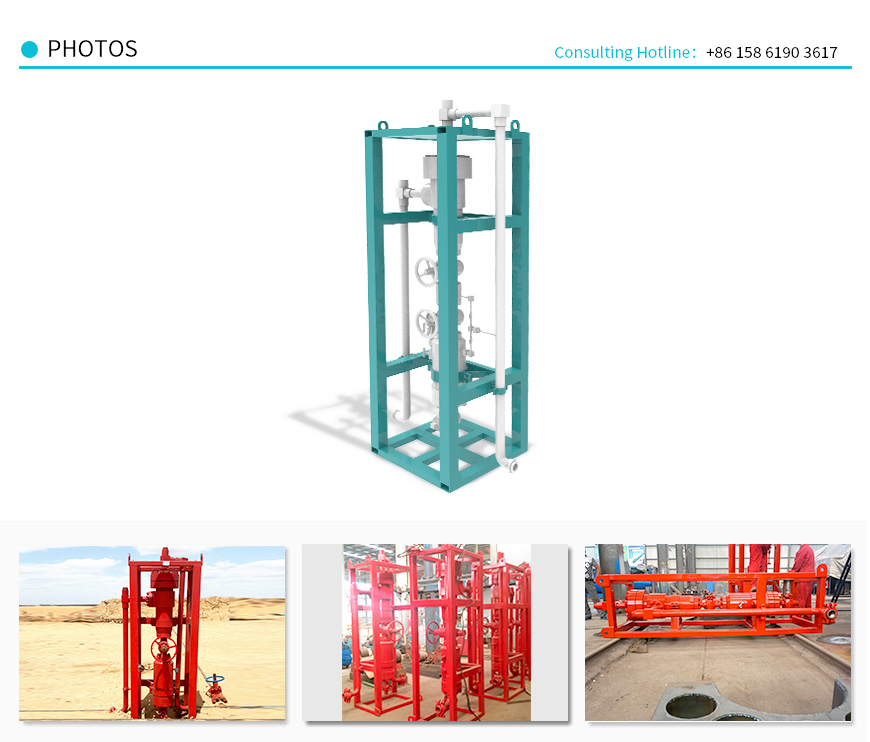

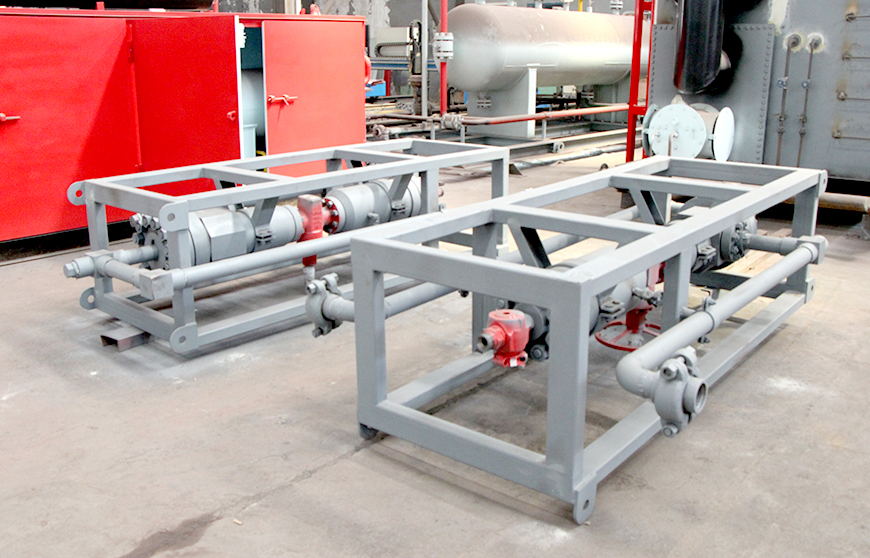

Cyclone desander is a wellhead desander used for surface equipment testing. It can provide effective and reliable separation of sand and solid from hydrocarbon and water in the early life (well cleaning) or production life (recovery of formation sand). According to the working principle of the rapid rotation of solid particles in the desander, the unit should be placed as close as possible to the wellhead (upstream of the choke manifold) to remove solids from high-speed wastewater before further processing of the fluid. During operation, the whole well flow is sent to the desander. In the separator, centrifugal force, centripetal buoyancy and fluid resistance are separated in the cyclone separator. The separated solids fall into a reservoir for separation, decompression and flushing. Performance depends on outlet conditions such as particle size distribution, outlet density versus particle, outlet viscosity and inlet velocity.

- Simple structure, high sand removal rate, small occupied area and easy installation;

- Simple operation, low maintenance cost and less investment;

- Can be used for high temperature, high pressure and corrosive gas, and can recover dry particles;

- In the process of uninterrupted oil supply, the sand in the oil can be removed for continuous operation;

- Medium pressure loss, small power consumption, can be used in various materials manufacturing;

- Large capacity and stable operation;

- Small in size, space-saving and convenient transportation;

- Economically and effectively protect downstream equipment from erosion and avoid secondary pollution;

- Can be customized according to actual needs.

Cyclone desander, also known as cyclone dust collector, is used to separate dust particles from air flow by centrifugal force generated by rotating air flow, which is used to separate dust particles with particle size greater than 5-10µm. It has a history of more than 100 years in industry.

| Model | Intake pressure | Average sand removal rate | Air inlet | Air outlet | Sand outlet DN 1/2 |

| MPa | % | DN | DN | mm | |

| LD-LRCS-1 | < 35 | > 96 | 65 | 65 | 32 |

| LD-LRCS-2 | < 70 | > 95 | 65 | 65 | 32 |

Leave a message

* is required

- *