ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617Filter desander

-

Filter desander is an efficient well head desander designed to remove sand and other solid particles from well effluent to prevent downstream equipment corrosion and extend the life of well test equipment. It is mainly used for post-fracturing sand well cleaning and maximum sand free rate testing.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

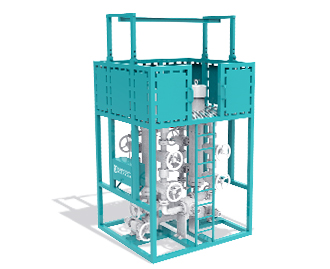

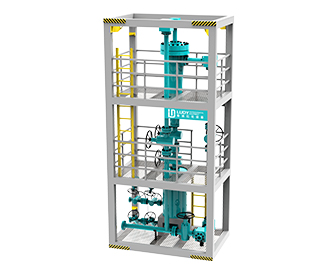

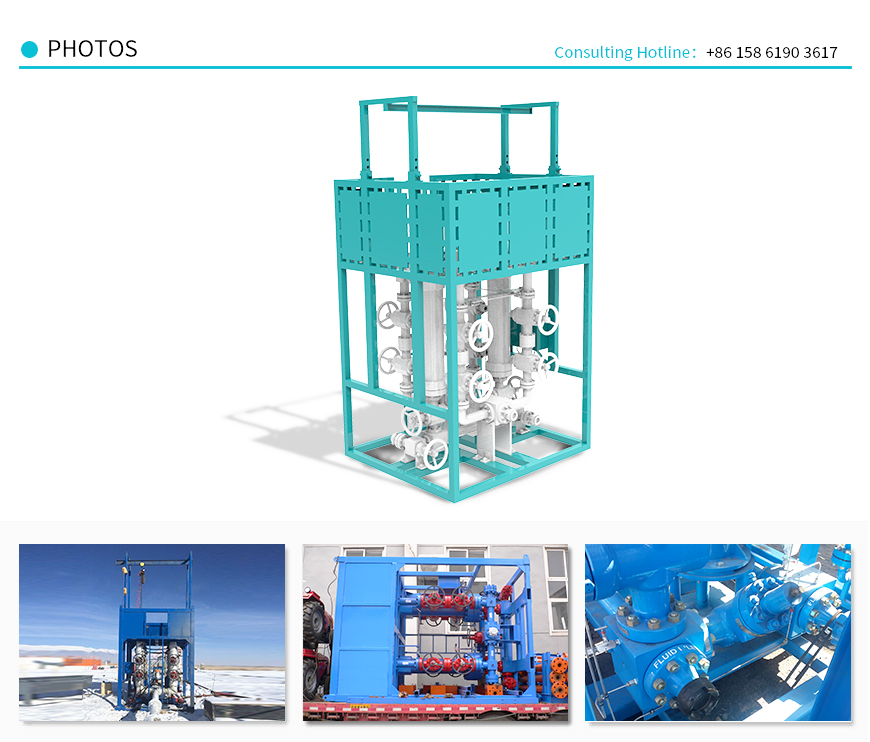

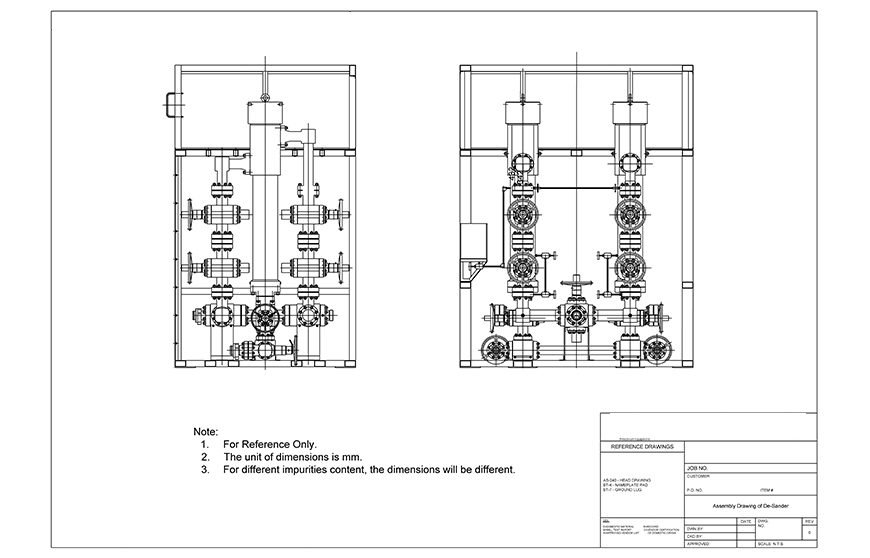

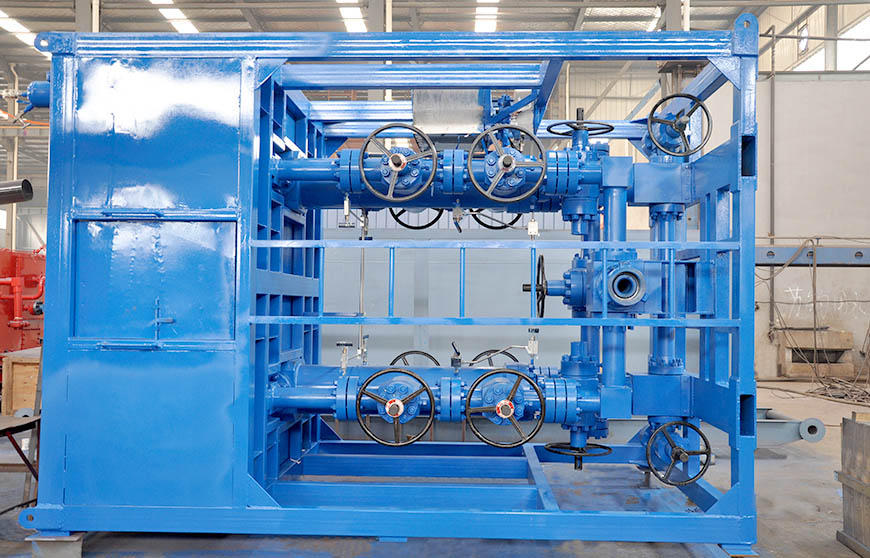

Filter desander is an efficient well head desander designed to remove sand and other solid particles from well effluent to prevent downstream equipment corrosion and extend the life of well test equipment. It is mainly used for post-fracturing sand well cleaning and maximum sand free rate testing. The filter is usually located downstream of the SSV and upstream of the choke manifold. Our dual-port filter desander separates and removes solid particles according to the principle of centrifugal force and gravity. After the outflow hits the baffle and enters the desander, it is refracted in all directions. Due to centrifugal force and gravity, the solid particles settle to the bottom of the screen, and the filtered liquid is discharged through the annular space between the screen and the desander.

The equipment can not only achieve the same effect as the imported device, but also has the effect of sulfur and acid prevention. It is suitable for the sand removal operation of high pressure, high production and acid bearing oil and gas wells. It can effectively remove the harmful solid debris such as fracturing sand, formation sand, ejection cartridge case, clay, heavy oil and other objects that affect surface transportation, testing and measurement.

Our dual-port desanding system consists of two 100% sand filter tanks, each with a high performance filter. Filters are used to process from the inside out, and mesh sizes vary from 100~400µm. The filter screen adopts wedge design, which has high backwash efficiency and shortens the off-line washing time to the maximum extent. The removed sand is collected in a sieve tube in the lower part of the vessel and directed to the sand handling system. To ensure maximum availability, the desander slide is equipped with a strainer and a double close valve for harsh operating conditions. The system is designed to allow isolation of the desander used for backwashing to remove trapped sand or debris. Skid-mounted crane is used to facilitate access from the top, as well as to check or replace the filter screen regularly.

- Exploration and well testing

- Production and online testing (including multiphase flow measurement)

- Extended well test

- Early production facilities

- Separation of sand and other solid particles from well flow

- Dual-cylinder system with high pressure bypass and double isolation valves

- Retractable lifting bracket for easy replacement of filter element

- Quick coupling on cylindrical vessels for quick replacement and maintenance of filter elements

- Optional water jet sand flushing system

- Optional sand box for sand treatment

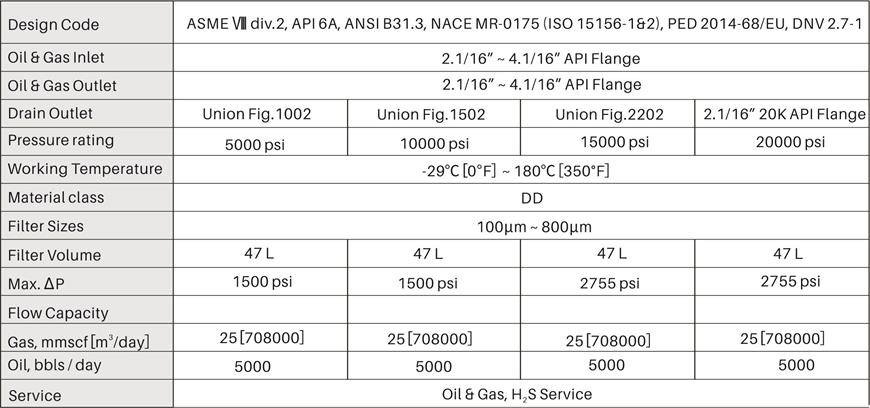

- Maximum working pressure: 70Mpa/105Mpa

- Maximum working temperature of fluid: 120℃

- Ambient temperature: -40℃~70℃

- Minimum storage temperature of the device: -50℃

- Working medium: oil, gas and water

- Maximum inner diameter of desander port: φ210mm

- Inlet and outlet size: 2-9/16″

- Volume of desander: ≥46L

- Natural gas processing capacity ≥150million m3/d

- Sulfur protection grade 10%

Leave a message

* is required

- *