ProductsProduct

-

Classification

Three-phase separator Multiport selector valve Manifold Gauge tank Gas booster skids Water bath heater LNG CNG Natural gas dehydration unit Debris catcher Heat exchanger Two-phase separator Multi-cyclone separator Gas sweetening units Pressure vessel Natural gas filter separator Natural gas circulation separator Buffer tank Desander Gas recovery unit

HOTLINE

+86 158 6190 3617Sour gas sweetening unit

-

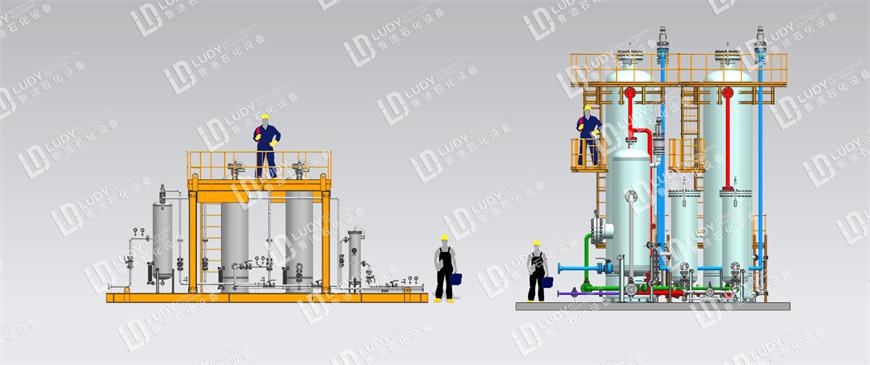

Sour gas sweetening unit is designed to remove hydrogen sulfide (H2S) by adsorption process and handle medium/large amount of natural gas. Gas sweetening units of Ludy Petrochemical Equipment is designed to remove effectively and safely hazardous H2S by using adsorption process.

- HOTLINE: +86 158 6190 3617

-

Details

-

Contact

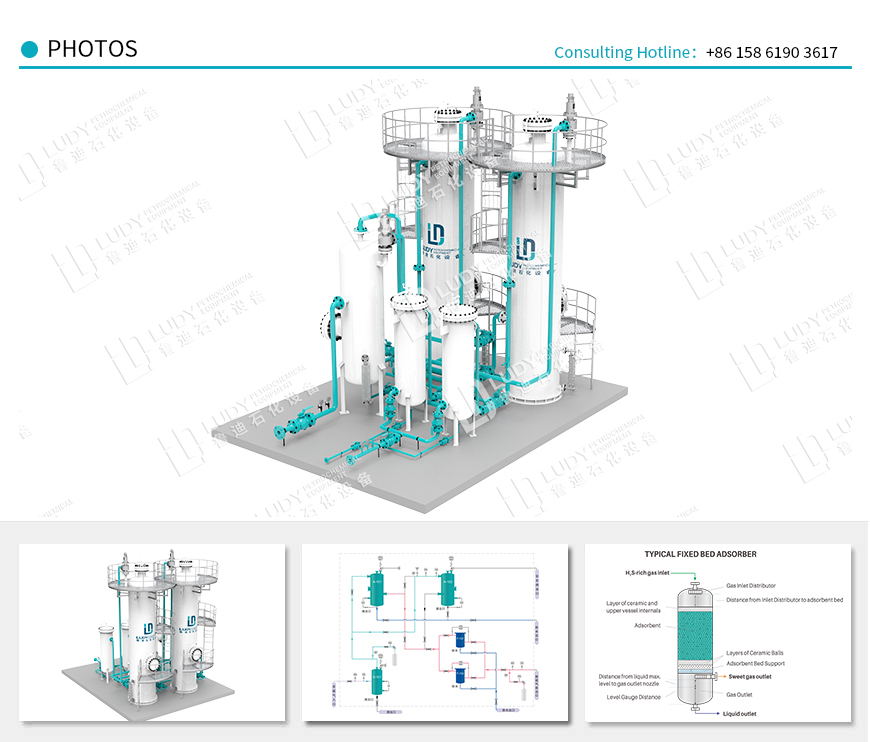

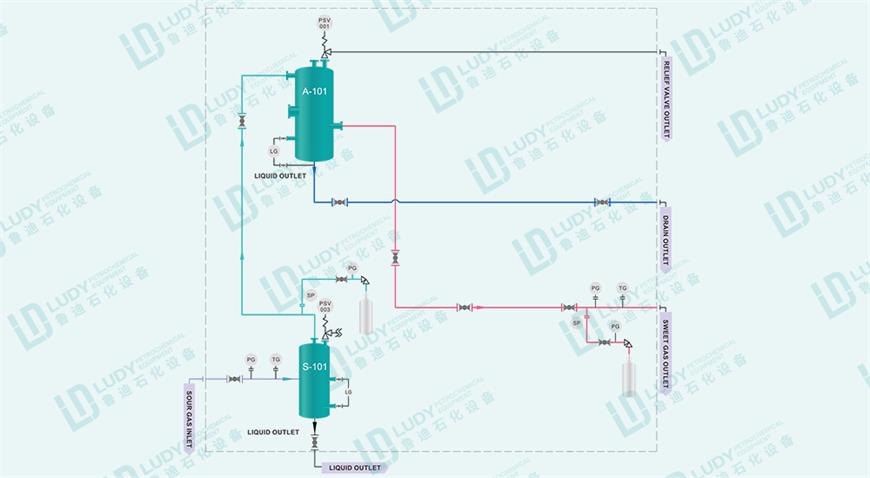

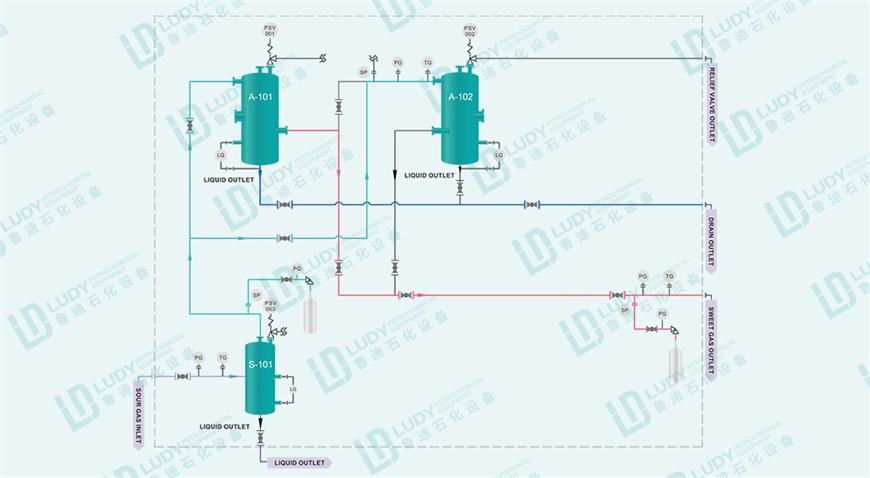

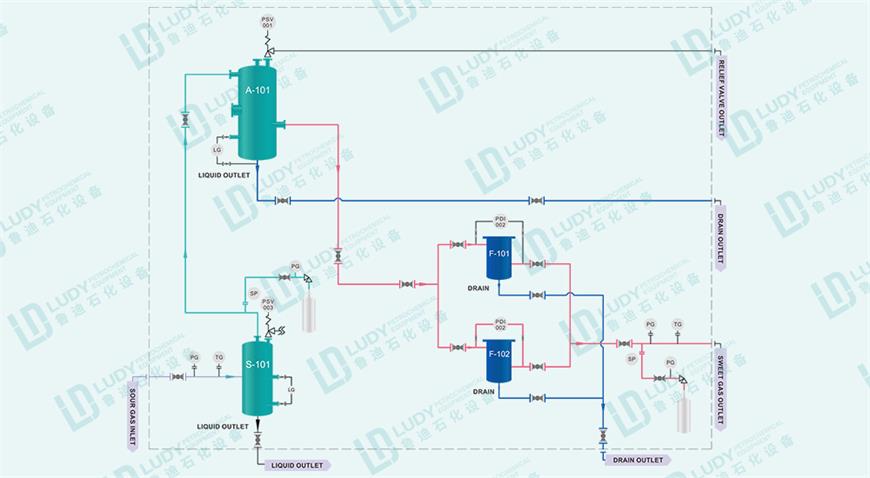

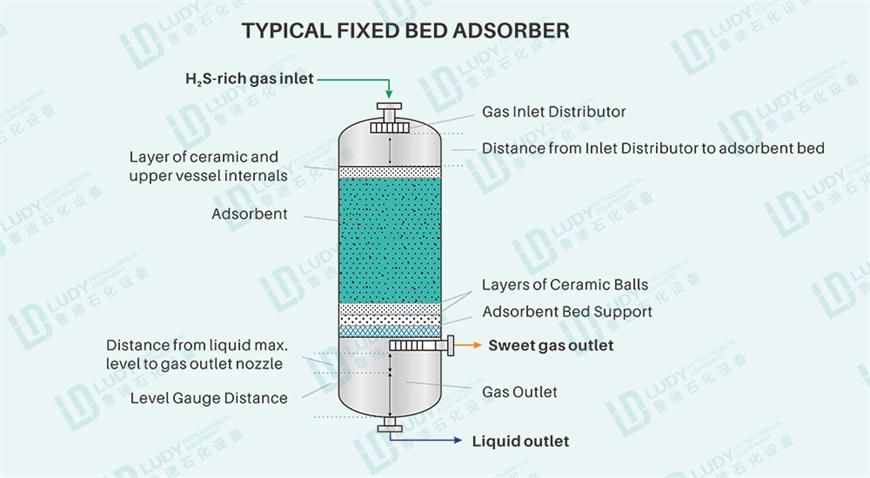

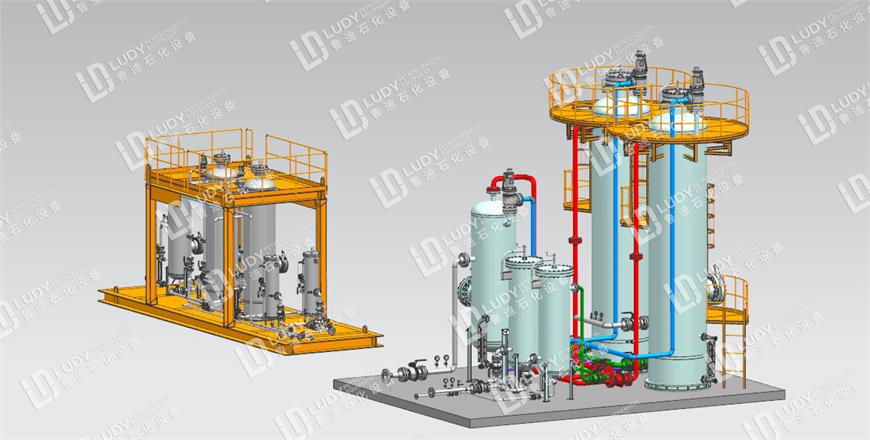

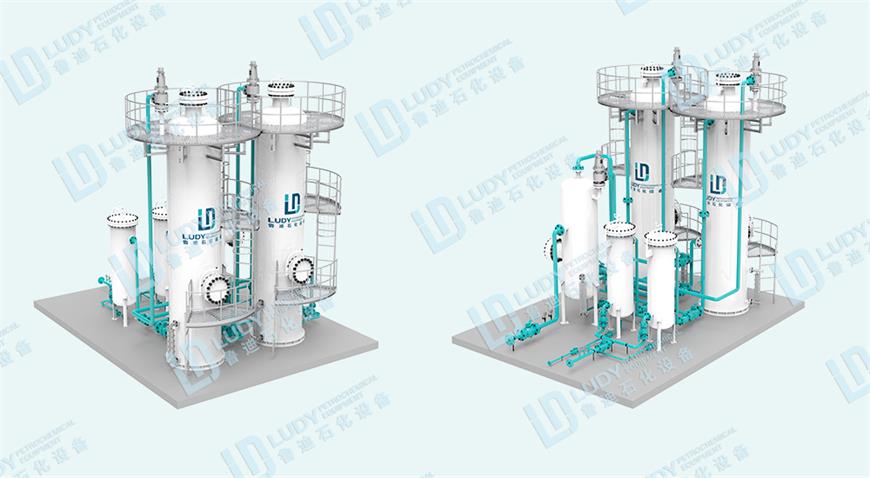

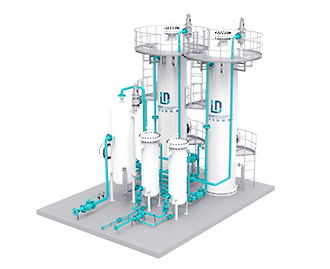

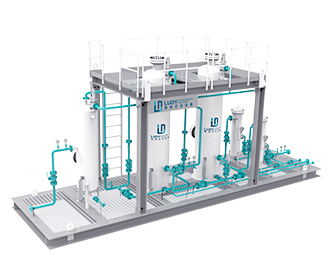

Sour gas sweetening unit is designed to remove hydrogen sulfide (H2S) by adsorption process and handle medium/large amount of natural gas. Gas Sweetening Units of Ludy Petrochemical Equipment is designed to remove effectively and safely hazardous H2S by using adsorption process. Gas Sweetening Unit consists of inlet gas-liquid separator, process columns fixed adsorbent bed, end gas filters, sampling ports, instruments, valves, safety devices, operating platforms, and other components specified in Ludy’s proposal.

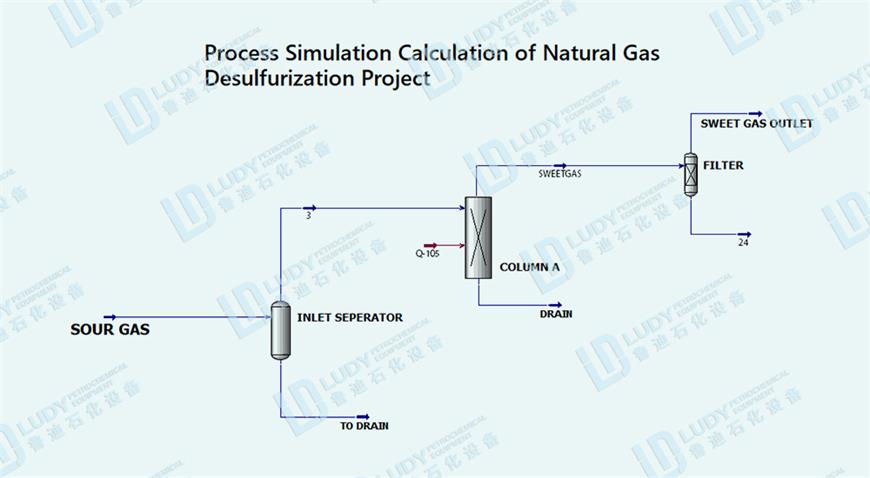

Ludy Petrochemical Equipment offers a variety options for hydrogen sulfide removal adsorbents. We use quality H2S adsorbents, such as iron-based solid H2S scavenger, activated carbon and other adsorbents specified in our product catalogue. Our design solutions range also includes molecular sieve gas sweetening units and amine sweetening units, which are alternative to high flow gas desulphurization. The main advantages of our Solid Bed Scavenger are high cost effectiveness, short delivery time and guaranteed process performance. Compared with molecular sieve and amine treatment processes, our solid bed scavenger requires the lowest operating cost. However, some process selection depends on operating conditions, such as H2S concentration in natural gas, natural gas flow, and customer preference for process flow. As one of the leading and qualified suppliers of natural gas desulfurization equipment in China. Our technical team is composed of senior process engineers, chemical engineers, mechanical engineers and electromechanical engineers, can provide you with the most advanced solutions.

Gas sweetening by iron sponge process usually involves several steps. The first step is to remove the droplets present in the raw natural gas. The droplet blocks the pore of the iron oxide adsorbent thus reducing the efficiency of the adsorption bed. At the center of all gas sweetening operations are process towers, usually two towers filled with H2S adsorbent, tower A and tower B. Another advantage of Ludy is the ability to provide multipurpose solutions. Tower A and Tower B are usually operated by one, with the other standby. That is, after the adsorption bed of Tower A is used up, the operator will switch the flow to tower B. At the same time, in the case of high H2S concentration, tower A and Tower B can be operated simultaneously. A dry gas filter is used to remove dust and small particles that may exist in sweet gas that flows downward through the adsorption bed and loses H2S. However, the configuration is entirely dependent on the requirements of the project. Ludy can either provide its own solutions or customize them to meet customer requirements.

Special process simulation software

- Reliable and stable for H2S removal

- Process guaranteed

- Easy to transport and installation (plug and play)

- Easy operation

- Optional gas sampling kits and gas analyzing systems

- Provide stable quality iron sponge

- Designed by qualified natural gas and chemical engineers

- Self-contained skid

- Digital control system

- ASME standard design or PED pressure vessel

- Conform to NACE MR0175/ISO 15156

- Cost-effective

- Fast delivery period

.png)

Important Notes:

- Given parameters are for reference only. In case of flow rate greater than 30000 Nm3/day, LUDY shall conduct study of the client’s requirements and provide suitable solution for greater flow rates. Please contact us for technical assistance.

- In case of H2S content in natural gas stream is between 1000 ppm and 10,000 ppm, LUDY will study provide process data, in order to deal with greater amounts of hydrogen sulfide to provide appropriate solutions.

- It is necessary to provide the natural gas flow rate, pressure, temperature and composition list of natural gas, including the content of hydrogen sulfide, mercaptan, sulfide, carbon dioxide and other substances, water dew point, hydrocarbon dew point and other process data for customized design.

- Current parameters are for reference only. Each Solid Bed Scavenger is designed and fabricated according to the requirements of the project. Please contact us for technical assistance.

Ludy Petrochemical Equipment Co., Ltd. is one of the leading manufacturers and supplies of gas sweetening units in Asia. We provide quality equipment, cost-effective solutions that ensure process flow and strict compliance with customer specifications and standards. Please feel free to contact us for more technical information and quotations of gas desulfurization units. We would be more than happy to serve you.

Leave a message

* is required

- *

.jpg)